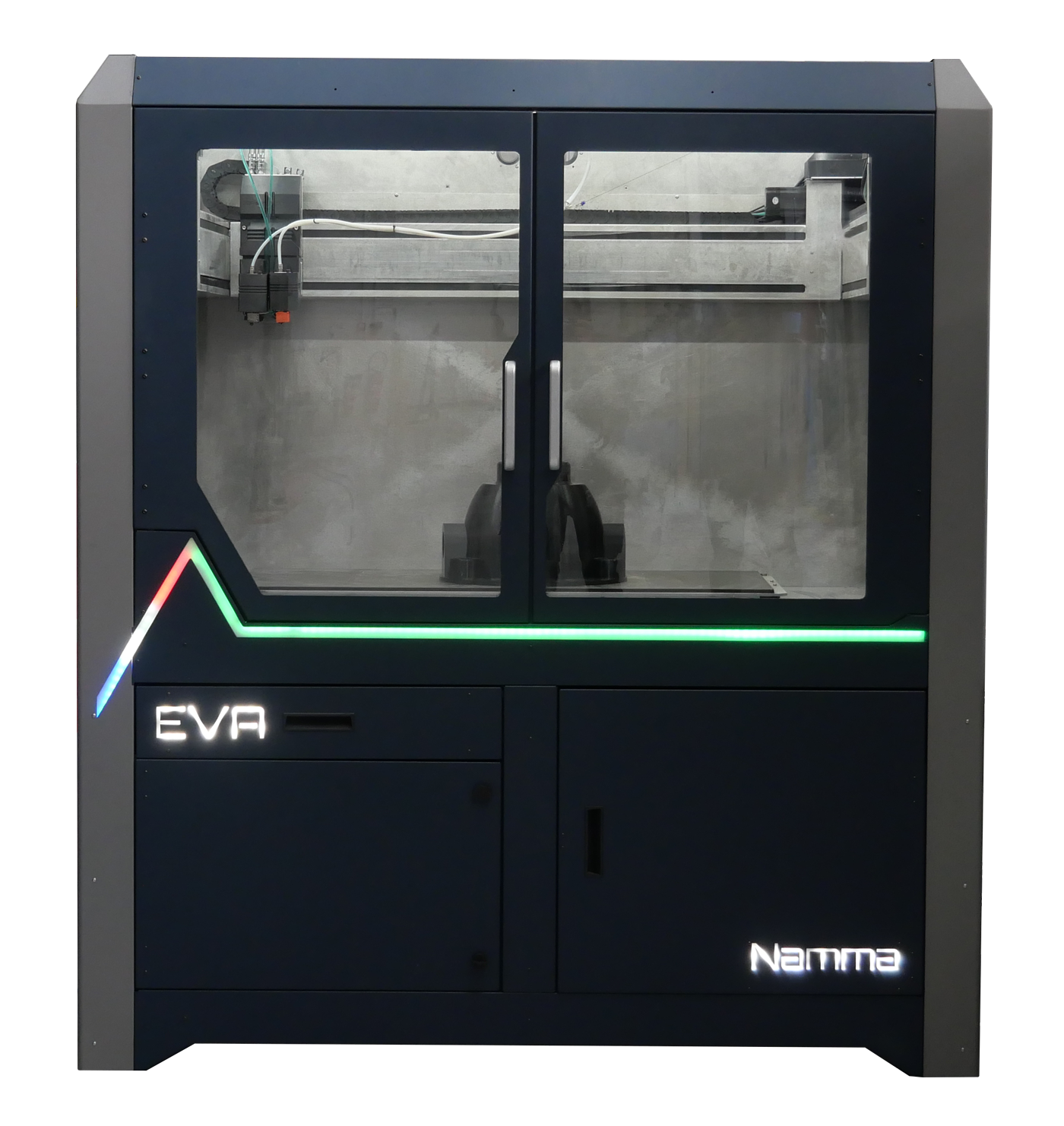

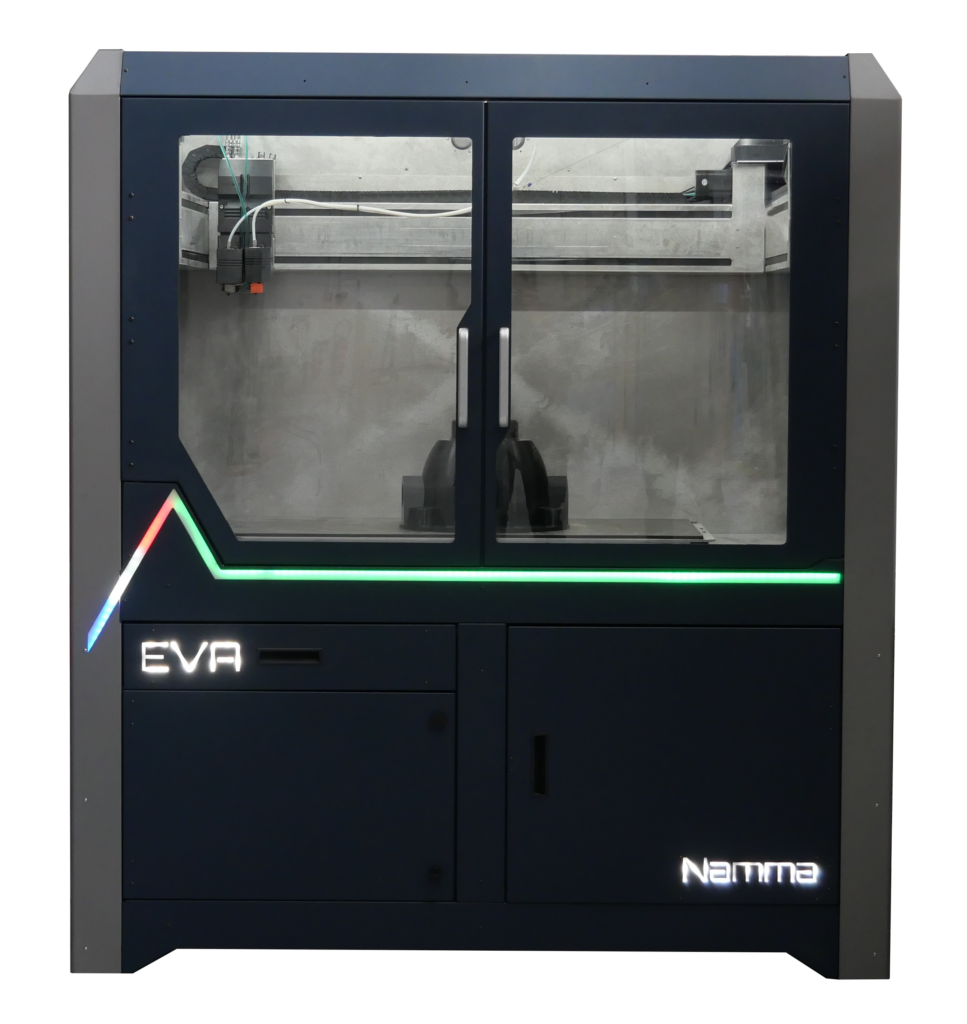

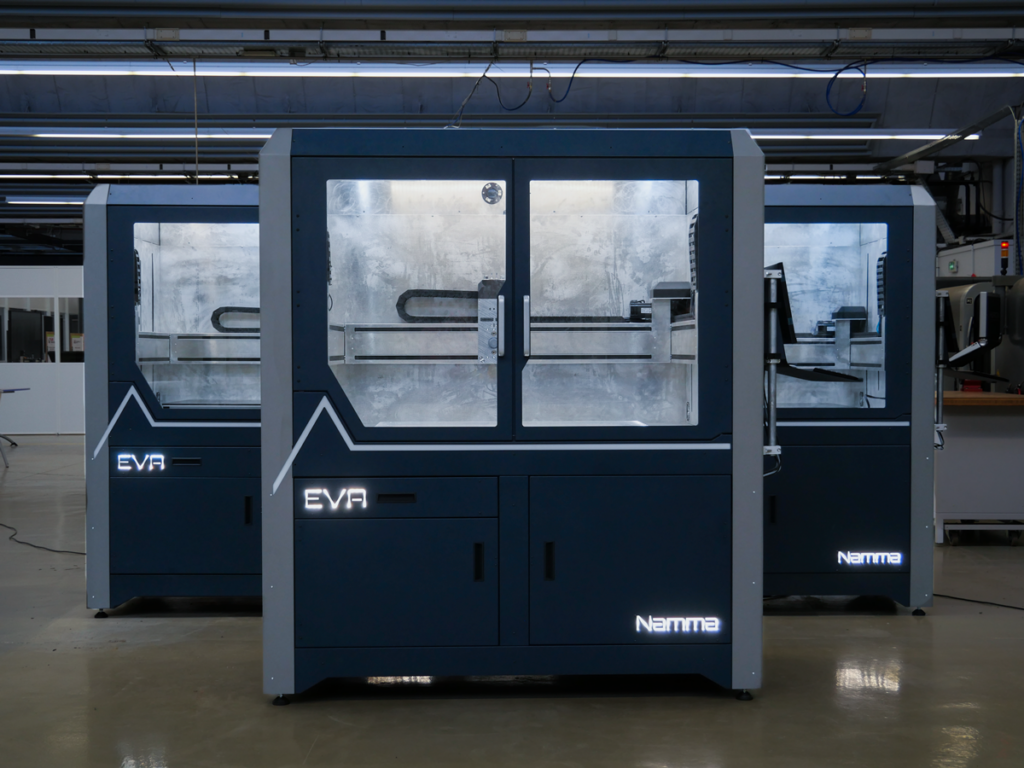

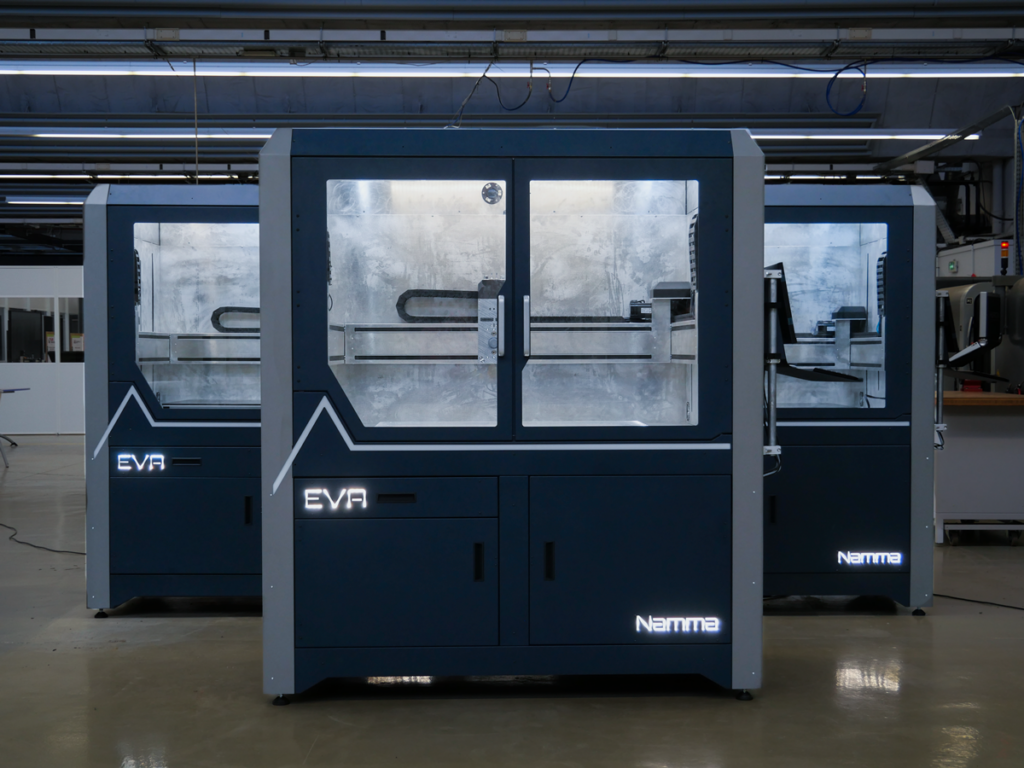

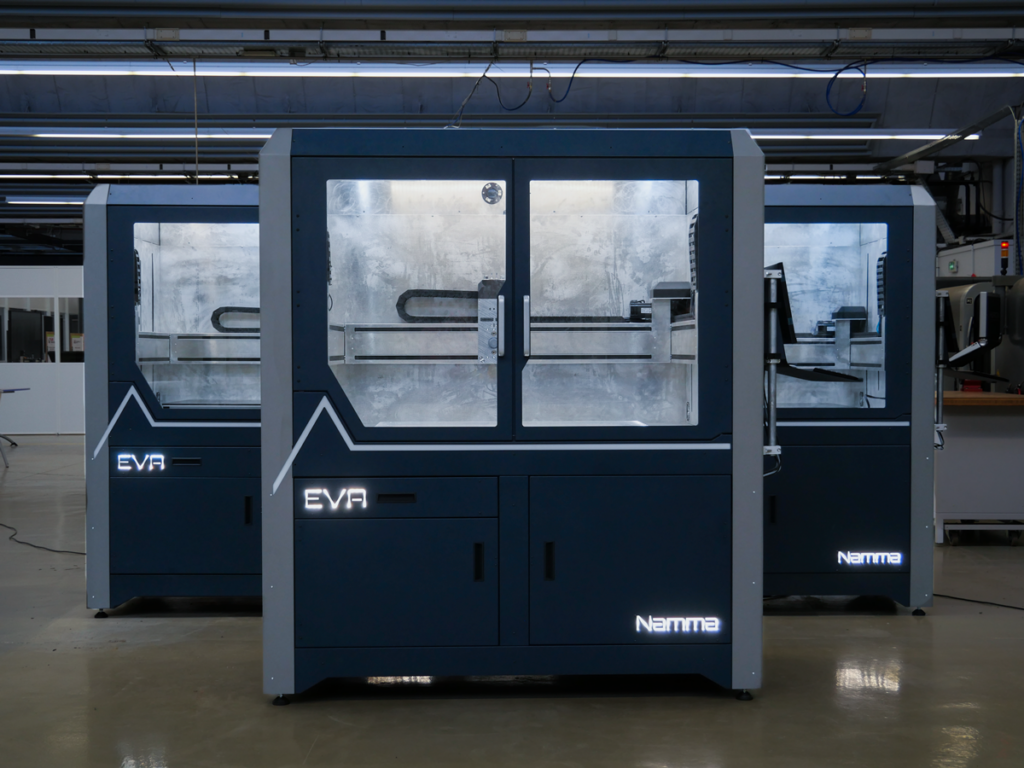

Multi-process 3D printer

EVA

3D PRINTING, CNC MACHINING, UV LASER

| ONE MACHINE

Gain in modularity and versatility

With 3D printing and machining, explore a variety of materials and applications to boost your innovation and responsiveness.

Choose between two large working volumes: 1000mm x 500mm x 500mm or 500mm x 500mm x 500mm, and manufacture one-piece parts to scale 1 and large series of parts to meet variations in activity.

Thanks to its N-Play piloting software, EVA can be adapted to suit both beginners and experienced pilots.

EVA is a technological solution for manufacturers. All our machines are manufactured and assembled in France.

Trusted by

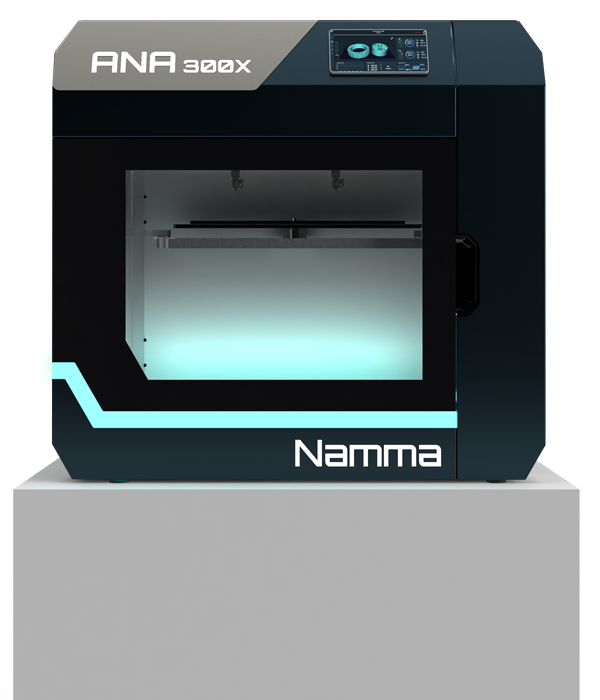

Multi-process 3D printer

EVA

3D PRINTING, CNC MACHINING, UV LASER

IN ONE MACHINE

Trusted by

3 processes in 1 machine

3D PRINTING

MACHINING

LASER

3 PROCESSES, 1 MACHINE

3D PRINTING

MACHINING

LASER

High volume 3D printing

EVA is manufactured in large sizes. The EVA range is available in 2 different sizes: EVA and EVA500. Print one-piece parts or produce batches for increased production.

EVA

1000mm (L)

x 500mm (l) x 500mm (h)

EVA500

500mm (L)

x 500mm (l) x 500mm (h)

EVA

1000mm (L)

x 500mm (l) x 500mm (h)

EVA500

500mm (L)

x 500mm (l) x 500mm (h)

High industrial quality

Reduce your development times with EVA and its multiple tool heads to meet the challenges of Industry 4.0. Switch from one process to another without changing machines or operators: it’s now possible with EVA.

High-temperature components

nozzle : 500°C bed : 120°C

Coil compartment and environment

heated at 60°C

Robust chassis and precise transmission system

High industrial quality

Reduce your development times with EVA and its multiple tool heads to meet the challenges of Industry 4.0. Switch from one process to another without changing machine or operator: it’s now possible with EVA.

High-temperature components

nozzle : 500°C bed : 120°C

Coil compartment and environment

heated at 60°C

Robust chassis and precise transmission system

Equally effective whatever the process

Go from a large-format industrial 3D printer to a real machining centre for producing structural metal parts.

Change processes in less than

1 minute

Spindle power up to

2,2kW

Spindle speed up to

24 000 rpm

+ than 160 compatible materials

Choose the materials that meet your requirements in the form of filaments, granules, blocks and sheets, with a wide range of filaments from different EVA-compatible suppliers. You can also take advantage of Namma’s range of industrial materials: N-MAT.

3D PRINTING

MACHINING

LASER

3D Printing

- ABS

- PETG

- TPU

- PA12 CF

- And more

Machining

- Aluminium

- Copper

- Composite

Laser

- Wood

- Composite

- Aluminium

- Copper

- Composites

- Wood

- Composites

High added value parts

Drastically reduce your costs, increase the speed of your developments and no longer depend on external factors.

- Prototype

- Final part

- Tools

- Model

- Hybrid part

ENGINE CRANKCASE

Materials

N-ABS

Dimensions

890mm x 376mm x 310mm

Manufacturing time

86h

Cost with EVA

680€

Cost of subcontracting

1 810€

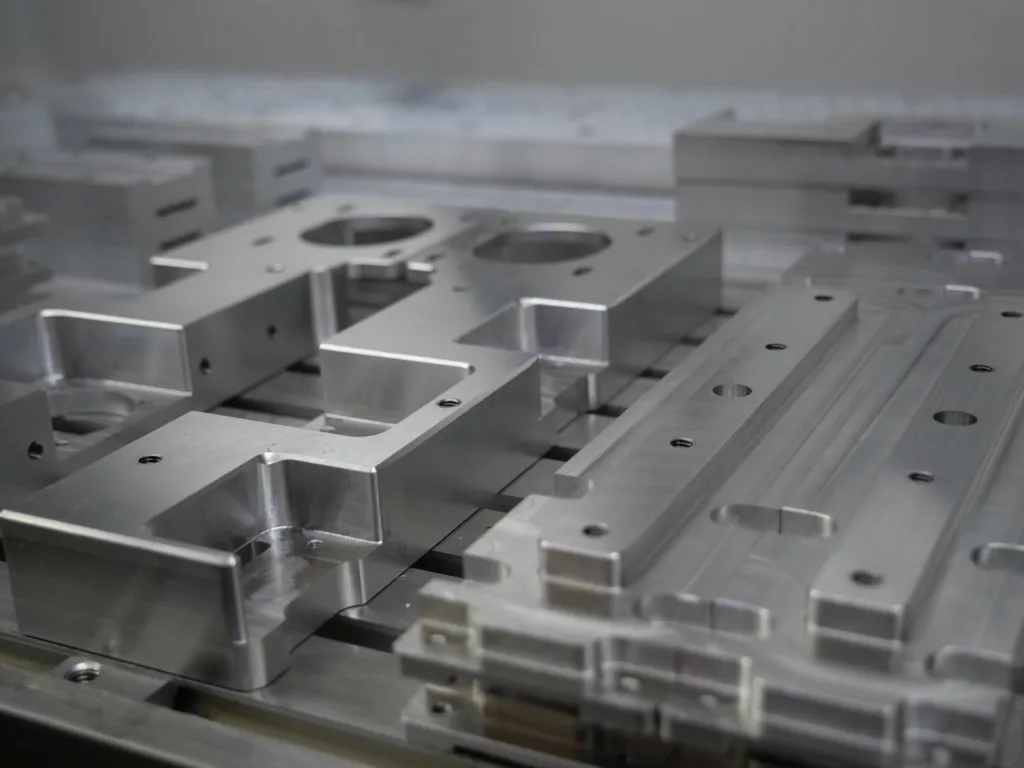

STRUCTURAL PARTS

Materials

Aluminium 2420

Dimensions

30mm x 50mm x 20mm

Manufacturing time

2h

Cost with EVA

50€

Cost of subcontracting

167€

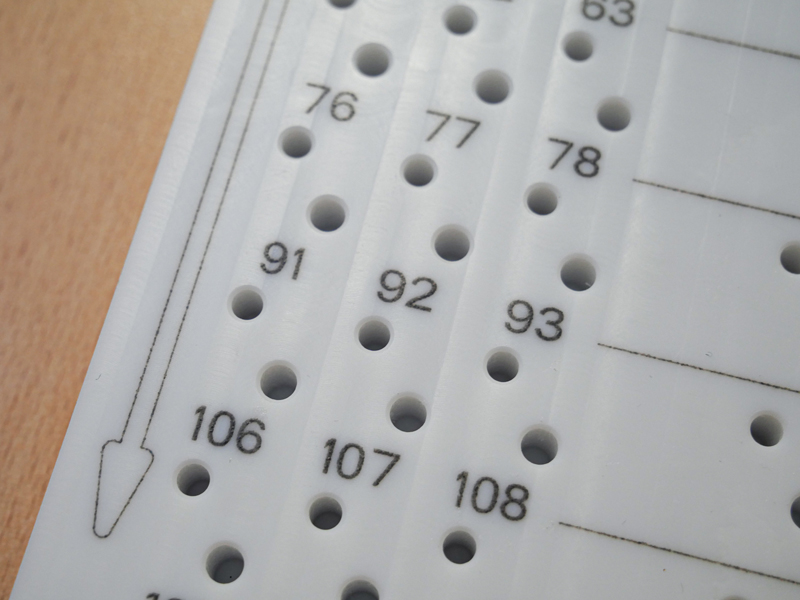

POSITIONING TOOLING

Materials

PET

Dimensions

350mm x 280mm x 20mm

Manufacturing time (machining + laser)

2h

Cost with EVA

105€

Cost of subcontracting

450€

PROPELLER

Materials

N-PETG

Dimensions

400mm x 400mm x 350mm

Manufacturing time

5h

Cost with EVA

130€

Cost of subcontracting

700€

THERMOFORMING MOULD

Materials

N-PA12 CF

Dimensions

300mm x 190mm x 45mm

Manufacturing time (3D printing + machining)

3h30

Cost with EVA

270€

Cost of subcontracting

1 500€

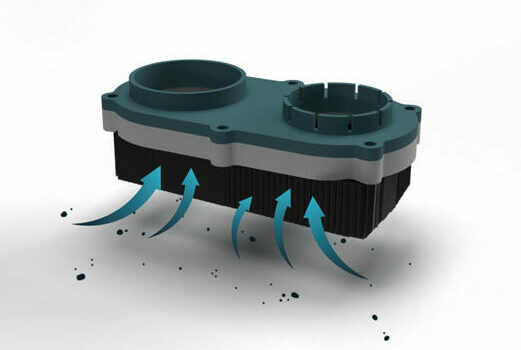

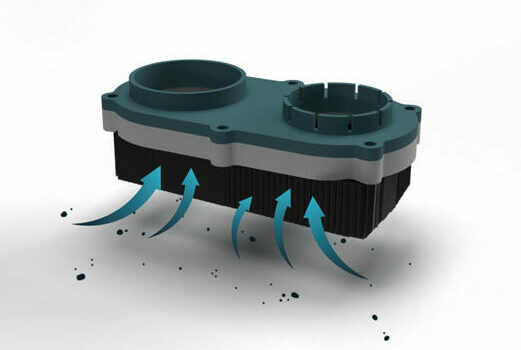

Filtration system

EVA benefits from a filtration system designed to capture extremely fine particles. EVA’s H14 HEPA filters offer one of the highest filtration efficiencies available to ensure maximum safety.

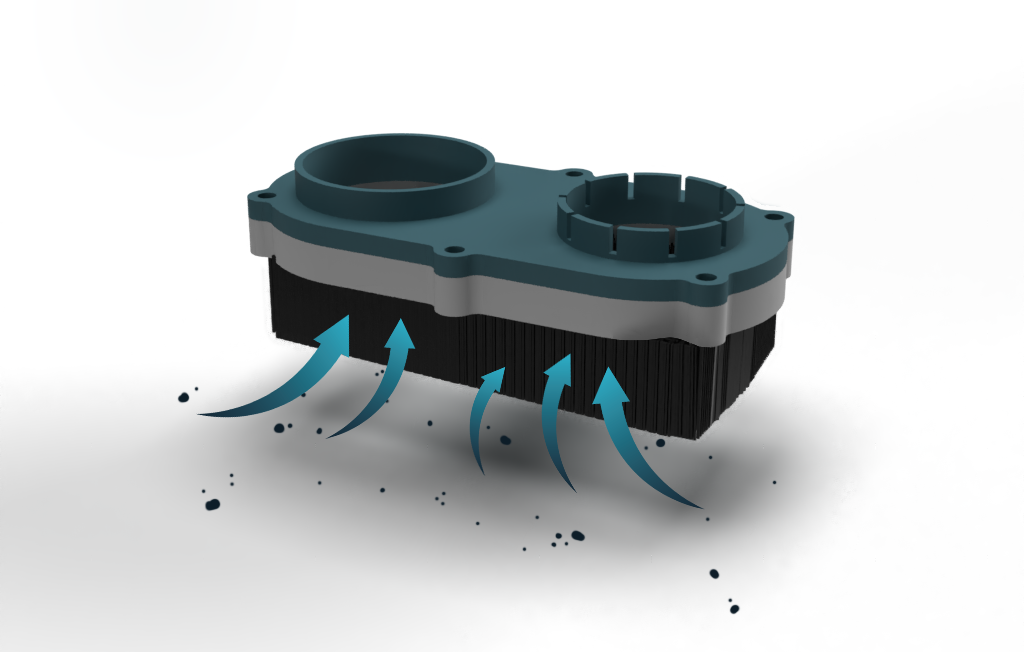

Chip extraction

EVA is equipped with a chip extraction system, guaranteeing a clean and healthy environment.

Chip extraction

EVA is equipped with a chip extraction system, guaranteeing a clean and healthy environment.

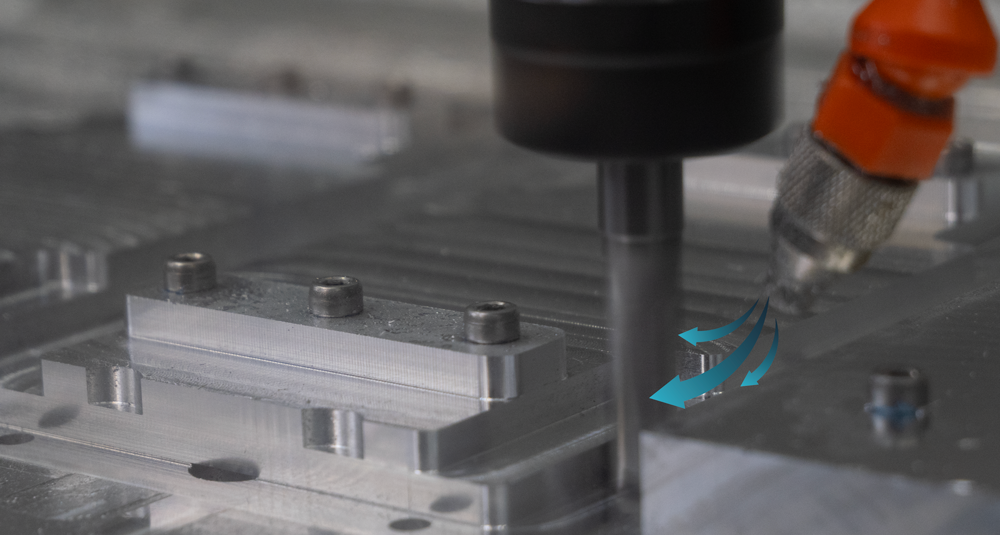

Micro-lubrication system

Micro-lubrication extends tool life and improves surface quality. The mixture of lubrication and air ensures a clean environment.

Certified machines

All Namma machines are CE certified in accordance with the Machinery Directive 2006/42/EC and comply with strict safety, health and protection standards. This certification makes it easier for you to integrate and install your future Namma machines in your company.

Comprehensive support

Namma offers you complete support from the moment you acquire a machine. Take advantage of training and maintenance for your Namma machines.

Accessible and Intuitive

EVA includes N-Play control software, directly accessible on a 22’ touch screen. This software allows you to control the machine simply and intuitively. Accessible to all types of user.

Made in France

Namma 3D printers are manufactured and assembled directly on our premises in Bordeaux. This environment means we can stay close to you and respond quickly to your needs.

By using French production methods, we can offer you high-quality, robust industrial products that comply with industry standards.

EVA adapts to your needs

1000mm x 500mm x 500mm

500mm x 500mm x 500mm

Bed temperature : 120°C

Heated chamber: 60°C

EVA

EVA500

Customer testimonial

What do our customers think?

Discover our different ranges

EVA adapts to your needs

EVA

1000mm x 500mm x 500mm

Bed temperature – 120°C

Heated enclosure – 60°C

EVA500

500mm x 500mm x 500mm

Bed temperature – 120°C

Heated enclosure – 60°C

Discover our machine ranges

THE ACQUISITION PROCESS

1. Get in touch

2. Appointment

of needs

4. Finalisation of

purchase

5. Gain in skills