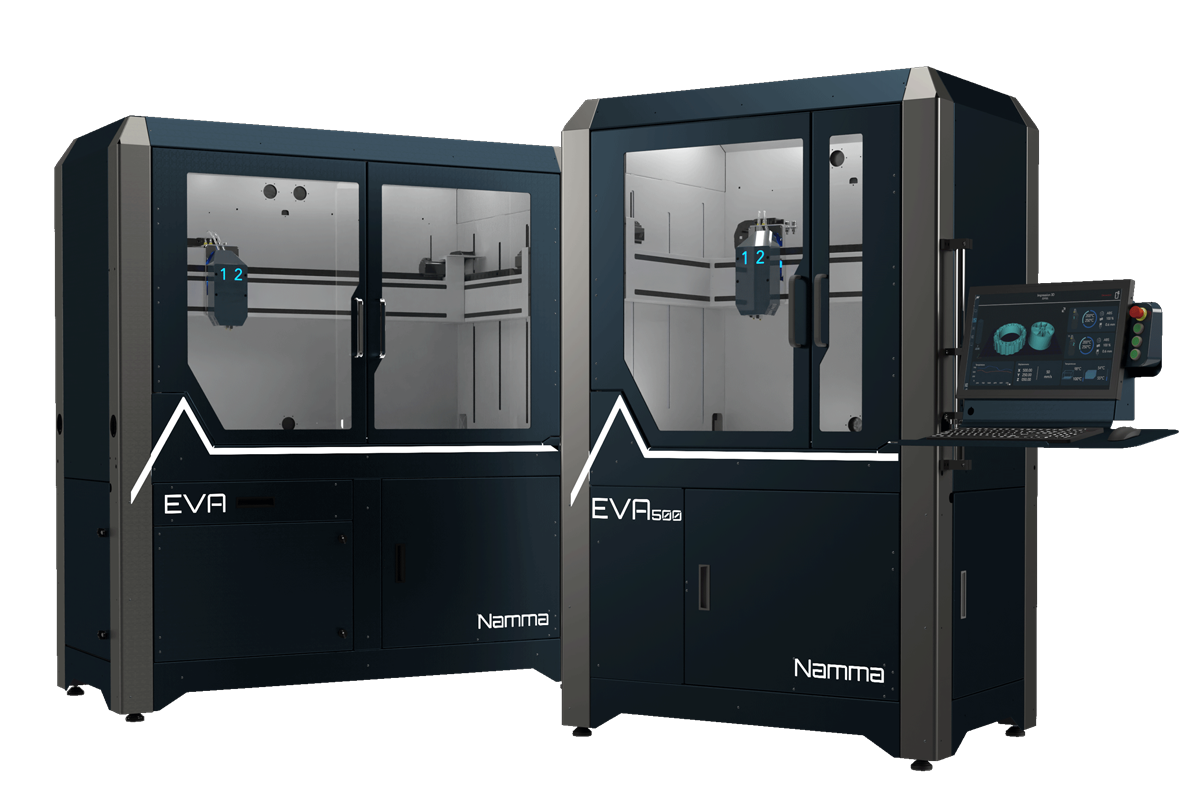

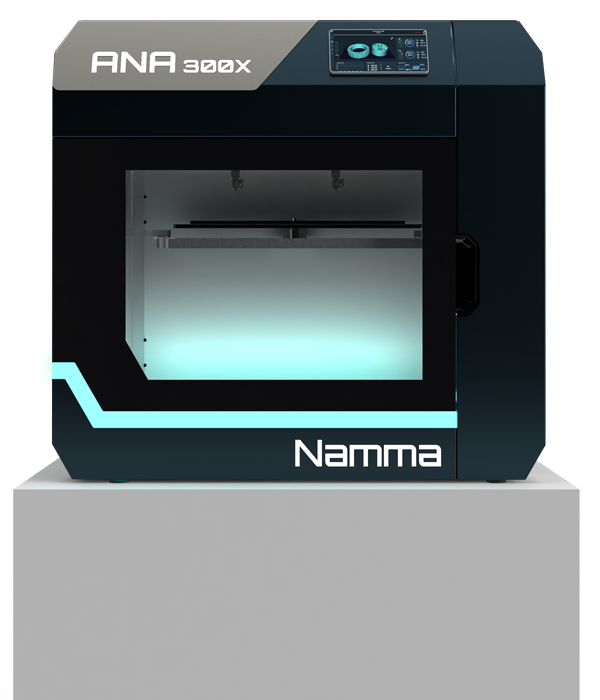

3D Printing tool head

3DF02

The versatile tool head

With the 3DF02 tool head, you can produce a wide variety of parts in 3D printing. Equipped with a liquid cooling system, it guarantees excellent thermal stability for printing technical materials.

Dual extrusion

Multi-material part manufacturing has never been easier with the dual extruder system with its two independent heads.

Modular

Change nozzles quickly and easily to suit your application. The 3DF02 offers you a wide variety of materials.

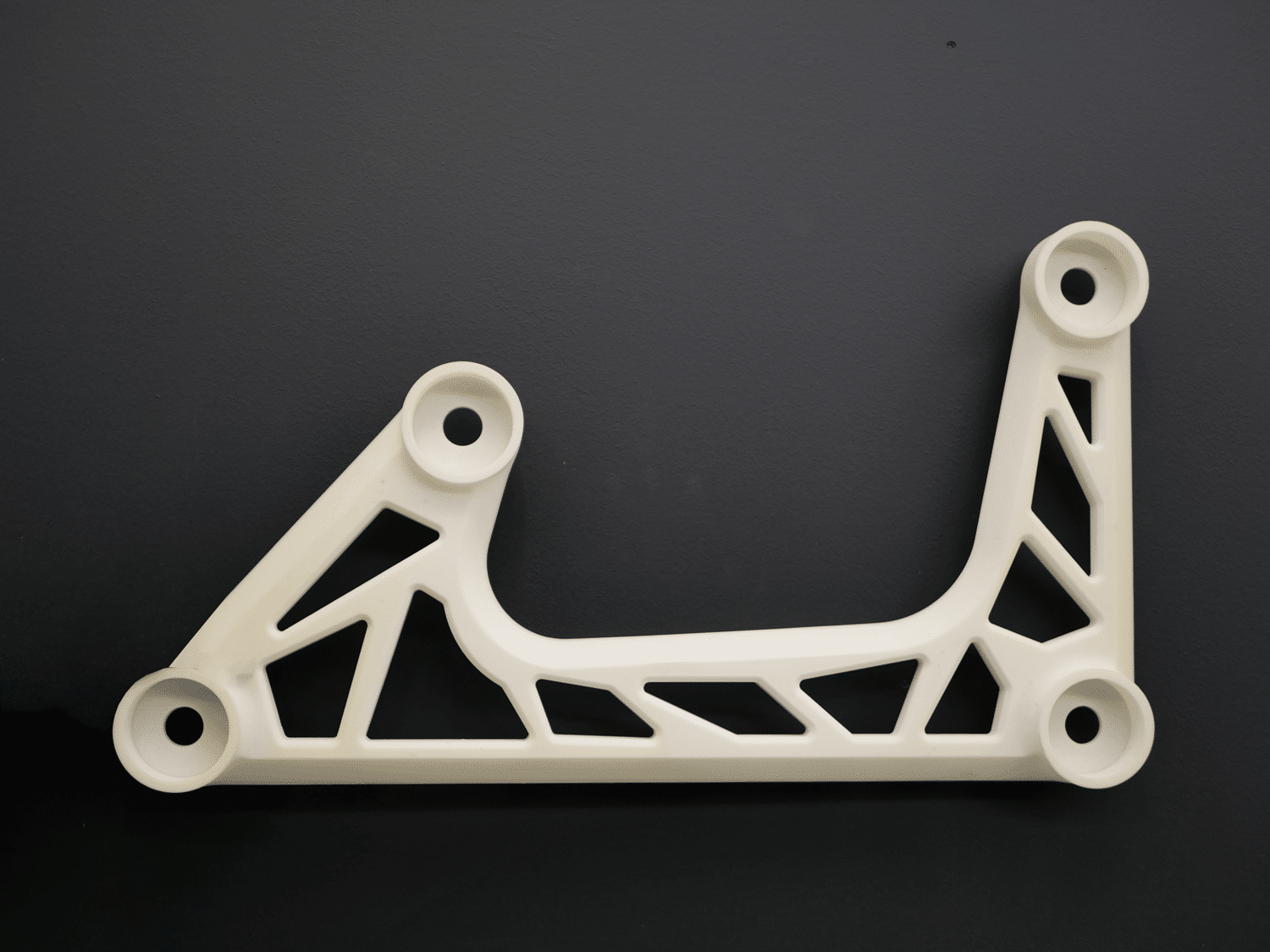

Precise parts with the 3DF02

Bracket model

Prototype of a drone chassis

3DF09

The high-speed tool head

Step up a gear with the 3DF09 tool head. A robust and powerful tool head for printing tough parts.

High flow rate

Reduce your printing time by 10 times with an extrusion rate of 0.9 kg/h. Achieve layer heights up to 1.5 mm.

Resistant parts

Print stronger parts with the 3DF09 with layer widths up to 10 mm.

High speed prints

Reduce your printing time by

10

3DP25

3DP08

Pellets tool head

With the 3DP25 and 3DP08 toolheads, scale up and 3D print parts at breakneck speed. Compatible with the EVA series, the 3DP25 and 3DP08 give you an extrusion rate 3 times faster than a high-speed filament toolhead.

Pellet extrusion

With pellets, reduce your material and manufacturing costs, while producing your parts even faster.

An infinite range of materials

Unlock the possibilities and access an infinite range of materials, including flexible materials with a wide choice of elasticity and high-performance materials.

Parts with complex geometries

With 3D printing in your machine, produce parts with complex geometries that only additive manufacturing can achieve. The 3DF02 allows you to produce parts with thin layers. With the 3DF09, get your final parts quickly.

Features

Complementary tool heads

- 3DF02

- 3DF09

- 3DP08

- 3DP25

| 3DF02 | 3DF09 | 3DP08 | 3DP25 | |

3999 /year | $3999 /year | $3999 /year | ||

| Technology | Fused Filament Fabrication (FFF) | Fused Filament Fabrication (FFF) | Fused Granulate Fabrication (FGF) | Fused Granulate Fabrication (FGF) |

| System | Double extrusion | Mono extrusion | Mono extrusion | Mono extrusion |

| Flow extrusion | 0.2 kg/h | 0.9 kg/h | 0,8 kg/h | 2,5 kg/h |

| Nozzle diameter | 0.4 to 1.2 mm | 0.6 mm to 2.5 mm | 0.4 mm to 2.5 mm | 1 mm to 5 mm |

| Heatcore | 1 heatcore by extruder | 2 heatcores by extruder | 2 heatcores by extruder | 3 heatcores |

| Material | Filament diameter : 1.75 mm | Filament diameter : 2.85 mm | Pellet size : 3 mm | Pellet size : 3 to 5 mm |

| Extrusion temperature | 300 °C | 500 °C | 450 °C | 500 °C |

| Intelligence | Tool detection, automatic bed probing with mapping | Tool detection | Tool detection | Tool detection |

| Water cooling | ||||

| End-of-material detection | Buy Now | Buy Now | Buy Now | Buy Now |

Compatible materials

Additive manufacturing

3D Printing

Fused Filament Fabrication

Additive manufacturing is the best way to go from idea to prototype quickly and cheaply.

Non-exhaustive list.

Uses: Functional prototypes, industrial molding, general purpose parts

Advantages: Impact resistant, durable, heat resistant

Uses: parts subject to high stresses

Advantages: mechanical strength, heat resistant

Uses: electronic card holders, electrical boxes

Advantages: shock resistant, heat resistant

Uses: ideal for outdoor parts

Advantages: UV resistant, weather resistant, high mechanical strength

Uses: printing support

Advantages: soluble

Applications: tooling, automotive, functional parts, medical

Advantages: high heat resistance (190°C), impact, abrasion and friction resistant, corrosion and chemical resistant

Uses: protective housings, functional prototyping, structural components

Advantages: high mechanical strength, high thermal resistance, historically used in industry

Uses: food contact parts (molds, containers), electrical components, medical prostheses

Advantages: waterproof, translucent, food safe, electrical insulator, light, easy to use

Uses: Models, design objects, packaging, marketing

Advantages : Easy to print, rigid, biodegradable, biosourced

Uses: assembly parts, belts, shells, protections

Advantages: flexible, impact resistant, tear resistant