INDUSTRY 4.0

CONNECTED INDUSTRY

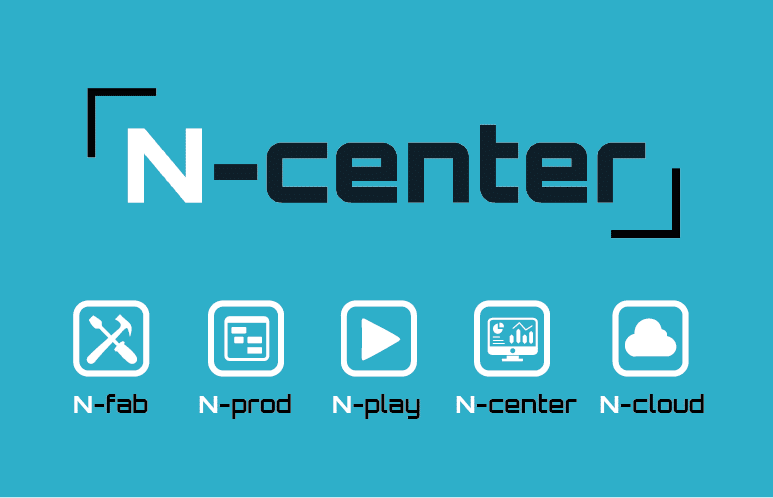

Imagine your flexible workshop with the N-Center software suite. It connects your EVA machines to each other and optimizes your production. Each EVA is dedicated to a specific task and process: 3D printing, machining or laser cutting/engraving. At any time, you can reorganize your production line with agility.

“A software suite present at every stage

of the manufacturing process.”

Software suite

Prepare your production

Manage your production

Pilote EVA

Remote control

Access your shared library

Customization

Whatever the sector, the current trend is towards customization. EVA is just as agile in custom manufacturing as it is in mass production. Make your parts to scale 1 to visualize manufacturing constraints and the final appearance of your part.

View part PV

The digital channel

Hybrid mold with QR Code

It is also possible to combine several processes on the same part: this is known as a hybrid part. In a paperless approach, you can 3D print your part and mark it with a QR code. This allows you to digitally visualize its manufacturing characteristics (manufacturing range and PV).

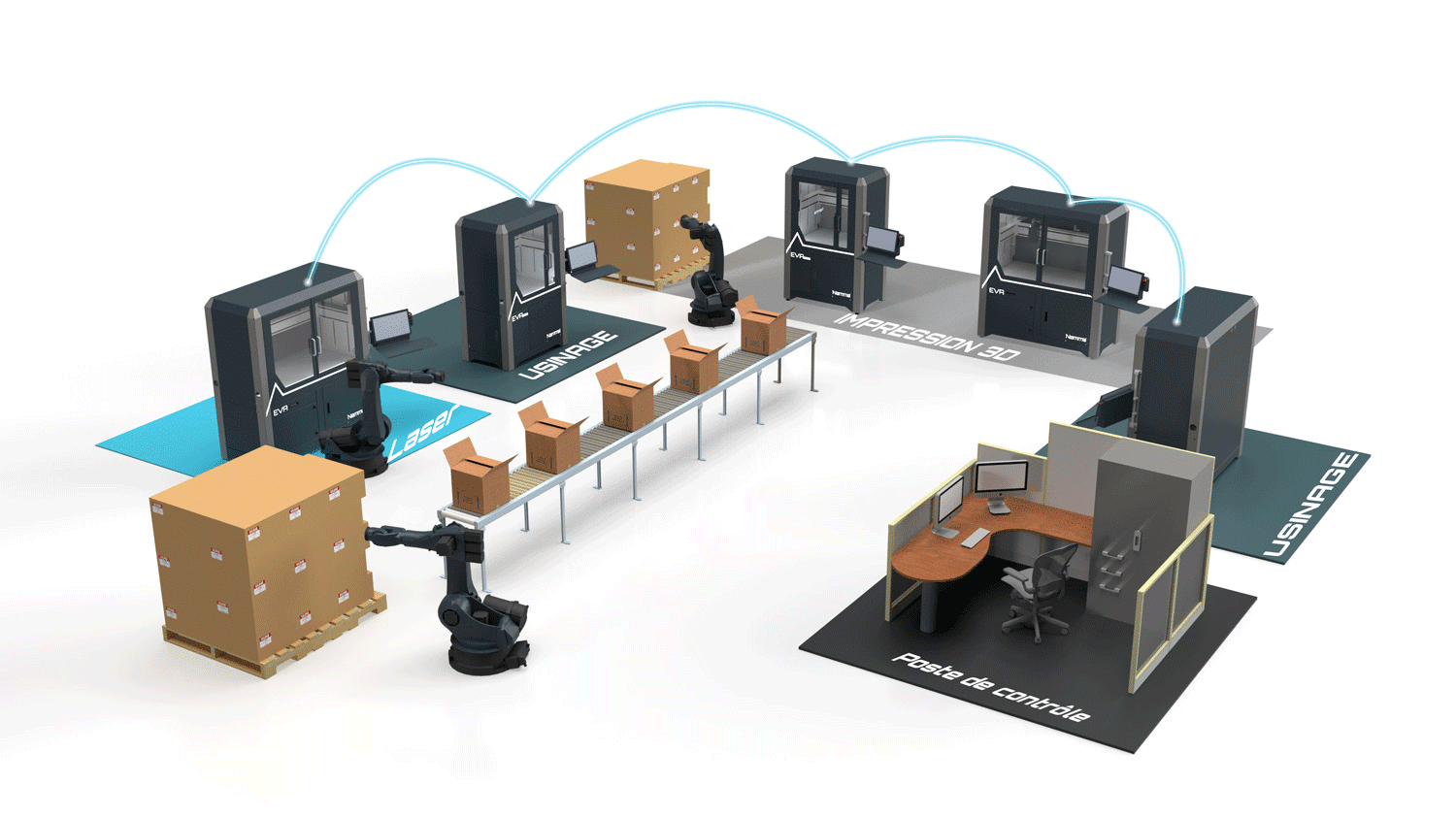

ULTRA-CONNECTED AGILE WORKSHOP

Control your production with the Namma ecosystem. Control your workshop according to demand, thanks to the compatibility of the different products in the range (EVA, EVA 500, N-Center software suite). Turn your workshop into a center for R&D, tooling production and final parts manufacturing as your workload evolves.

3D Printing Mode

CNC Mode

Laser engraving Mode

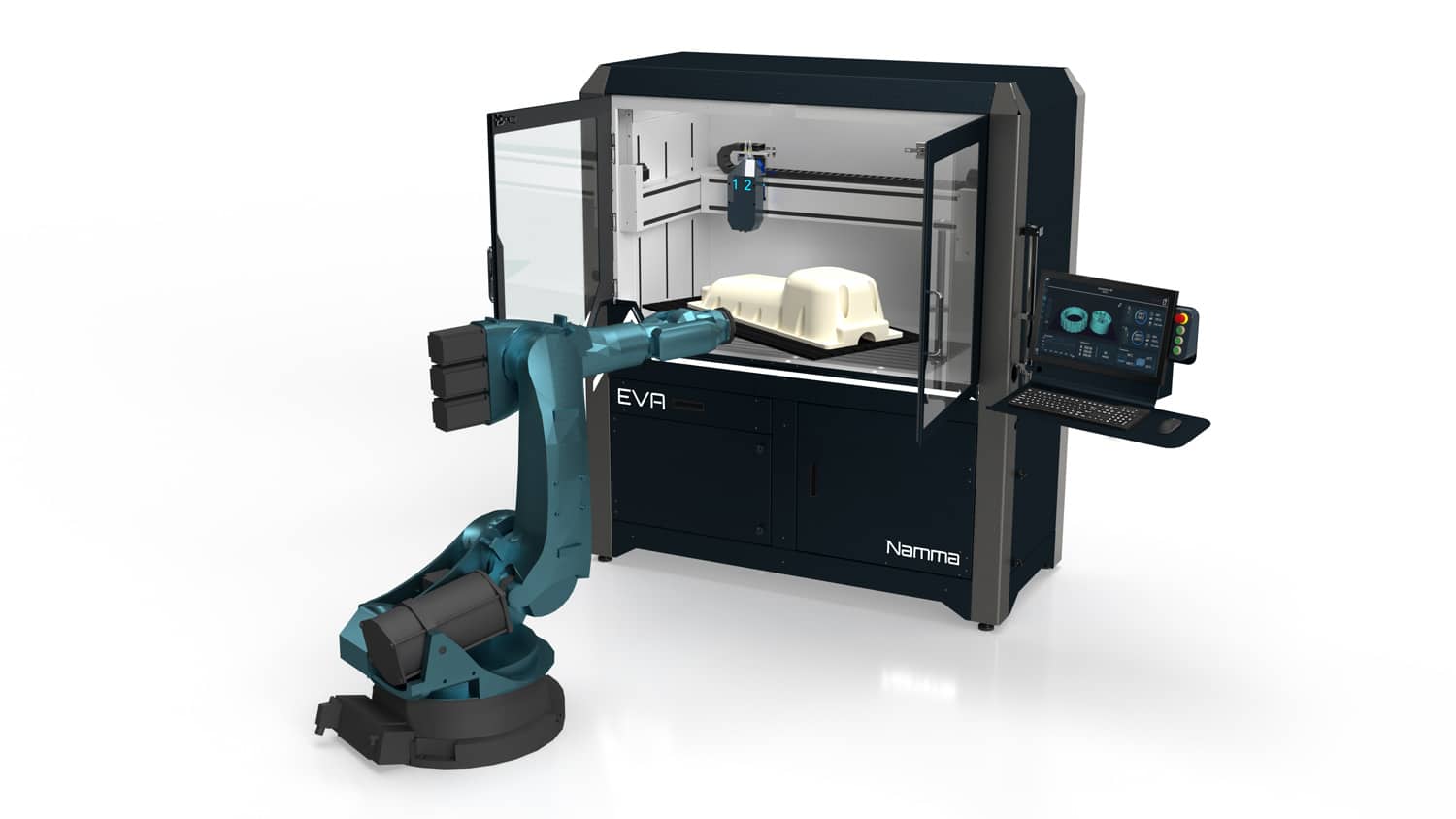

AUTOMATION

Industry 4.0 integrates robotic assistance to automate production. Indeed, our EVA machines are designed to facilitate collaboration with humans. Its interface enables connection with robotic systems, so you can, for example, extract the printing plate via one robot arm and clamp another. Turn your workshop into an autonomous manufacturing center.