What is IDEX 3D printing ?

3D printing is constantly evolving, with new innovations emerging every year to make its technologies more and more effective. It is in this context that the independent double extrusion system (IDEX 3D printing) has been appearing for a few years now.

This technology equips 3D printers with two independent 3D print heads, which can work simultaneously in the same machine. IDEX was originally developed to overcome the limitations of conventional 3D printers, which only have a single extruder, making some parts with a fragile cantilever.

IDEX 3D printing therefore has the same advantages as conventional 3D printing, and adds new benefits to the machines that can increase production capacity and meet your needs.

1. Different manufacturing methods

Two independent extruders offer a choice of different 3D printing modes.

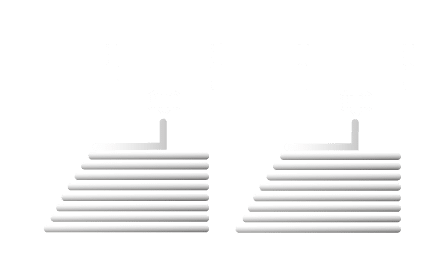

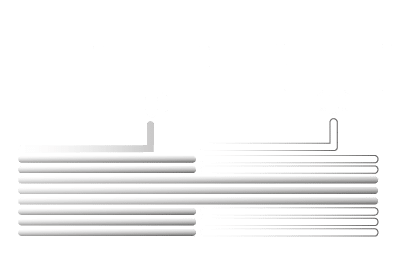

DUPLICATION

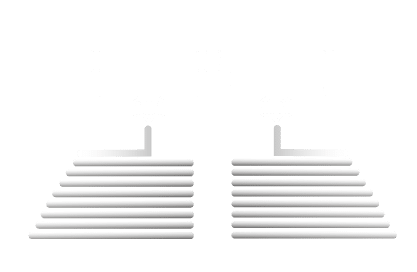

MIRROR

SUPPORT

Duplication

This mode enables two identical copies of the same model to be printed simultaneously. The two extruders move at the same time, each following the same path on one side of the platen. This feature is particularly useful when mass-producing parts at the same time.

Mirror

In mirror mode, the two 3D print heads diverge. In this case, two symmetrical copies are 3D printed simultaneously. This feature gives you 2 manufacturing choices: create independent symmetrical serial parts or divide a part into 2 parts so that each extruder prints half of it, which you can assemble at the end of the manufacturing process.

Support

Having two independent heads also makes it possible to create supports to make the part more stable and solid. In this way, one extruder will print the part and the other extruder will print its support simultaneously. This method offers great freedom of design and makes it possible to manufacture parts with complex geometries. It can also be used to manufacture a bi-material part, using two different materials.

With IDEX 3D printing, you can benefit from 3 different modes in a single machine. This technology gives you the flexibility and repeatability to adapt to your requirements, particularly in industry.

2. Economical

Thanks to its dual tool head, IDEX 3D printing can produce parts 2x faster. Thanks to its repeatability, by printing double parts simultaneously or with the support, it saves you a considerable amount of time in your production.

What’s more, IDEX technology not only saves you time, it also saves you money on materials, as a single 3D printer can do the work of two single-extruder machines.

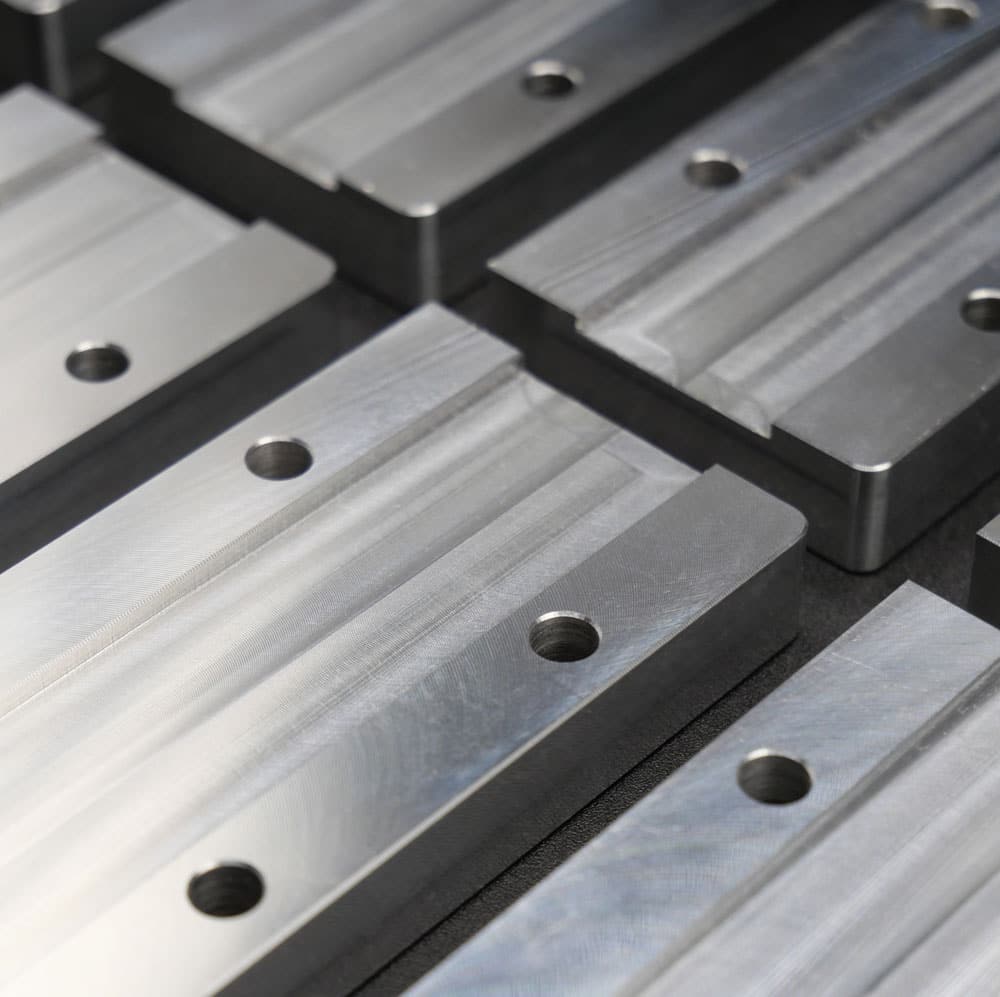

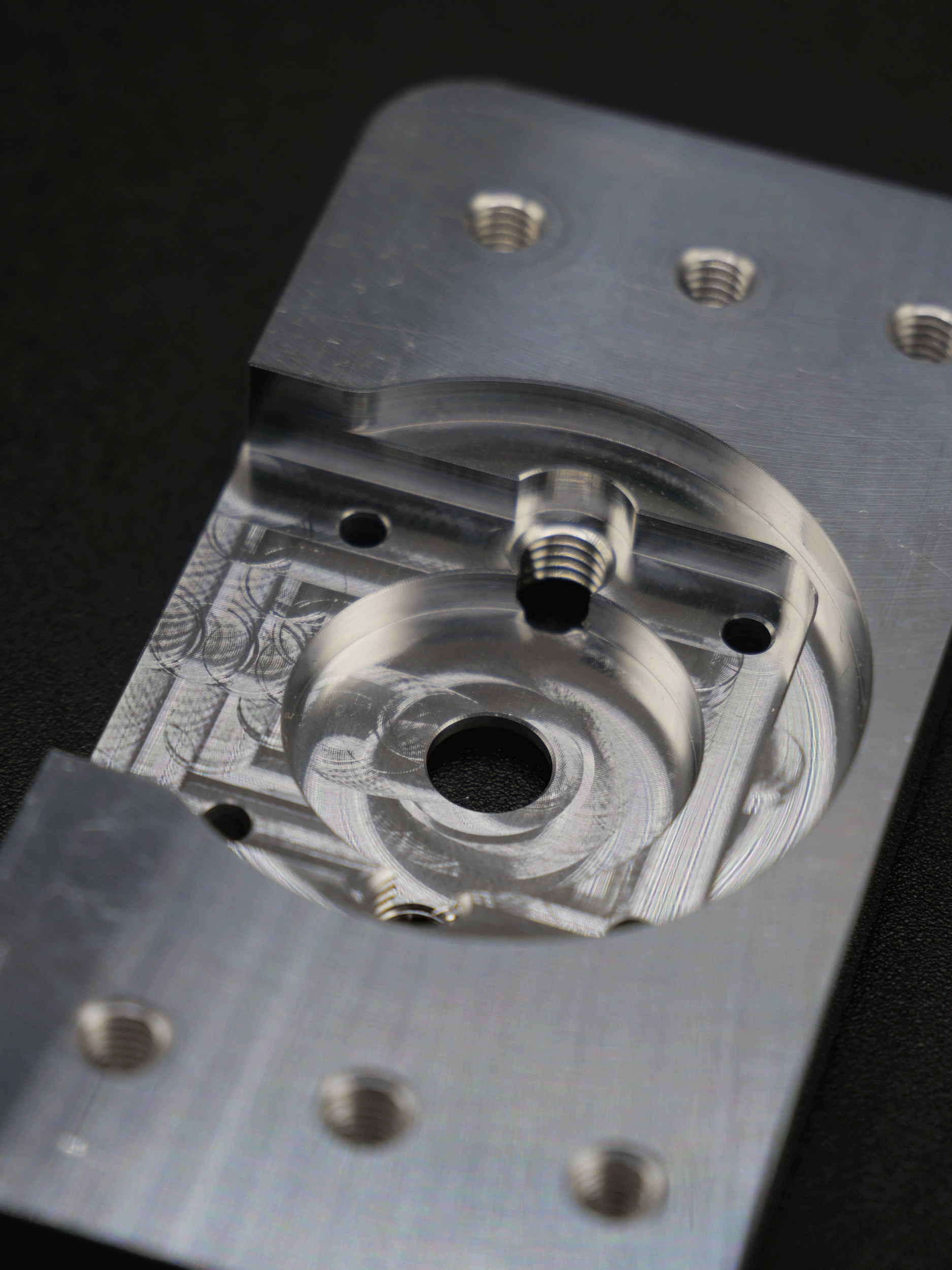

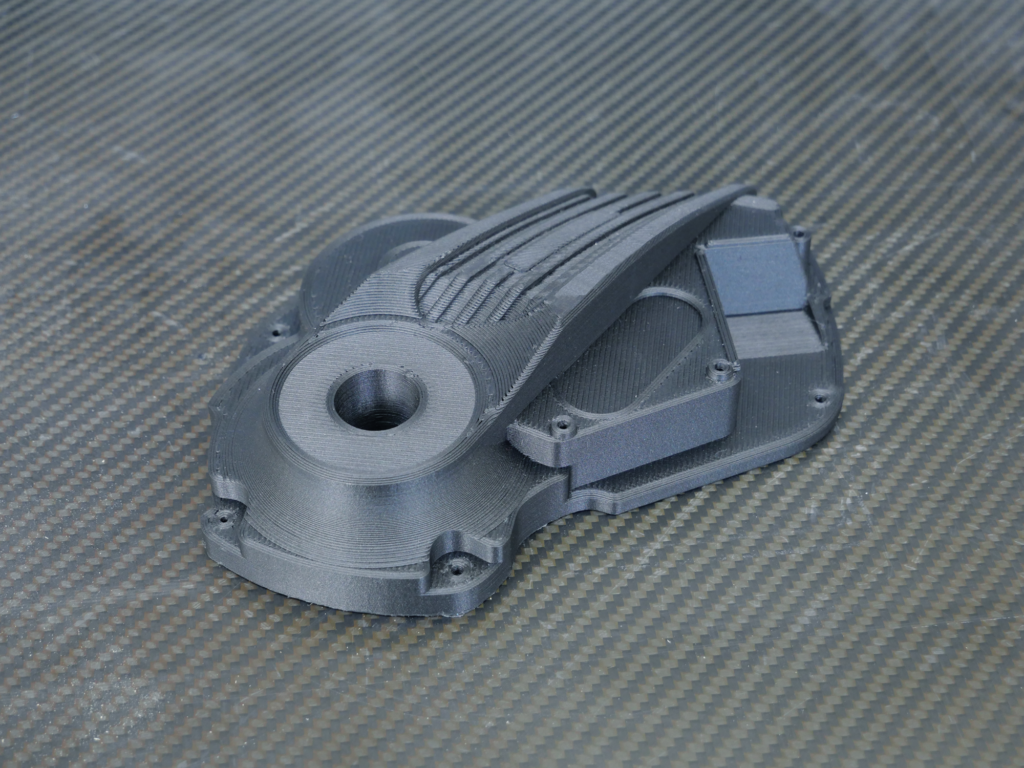

Namma’s ANA 300X IDEX 3D printer complements the speed of IDEX technology by offering an extruder travel speed of 200mm/s and an extrusion rate of up to 90mm3/s. It also offers a robust, industrial design.

3. Combination of materials

Thanks to its two independent extruders, IDEX 3D printing makes it possible to combine different materials on the same part or on two different parts simultaneously. This combination of materials makes it possible to obtain different mechanical properties on the same part to design more robust or flexible parts. It can also be used to manufacture directly two-coloured parts using two different colours of filament for aesthetic or mechanical differentiation purposes.

The use of multi-materials also makes it possible to create soluble supports for complex parts, with support structures that can be easily dissolved after printing.

IDEX technology adds numerous advantages to 3D printing. The presence of two extruders offers versatility, speed and flexibility within the various manufacturing processes. Find out more about IDEX 3D printing with Namma’s IDEX 3D printer: ANA 300X. Its advantages:

- Industrial-qualified and robust

- Dimensions of 300mm x 300mm x 300mm

- Easy to use thanks to N-Play software

- Open to all materials and compatible with N-Mat materials

- A Made In France machine

usinage pièce métal Machining: metal parts machined in less than 1 hour? In a constantly evolving industrial environment, machine manufacturers are constantly …

Your industrial tools at your fingertips In a constantly evolving industrial environment, controlling the production of tooling is a key issue for …