Hybrid 3D printer:

industrial precision

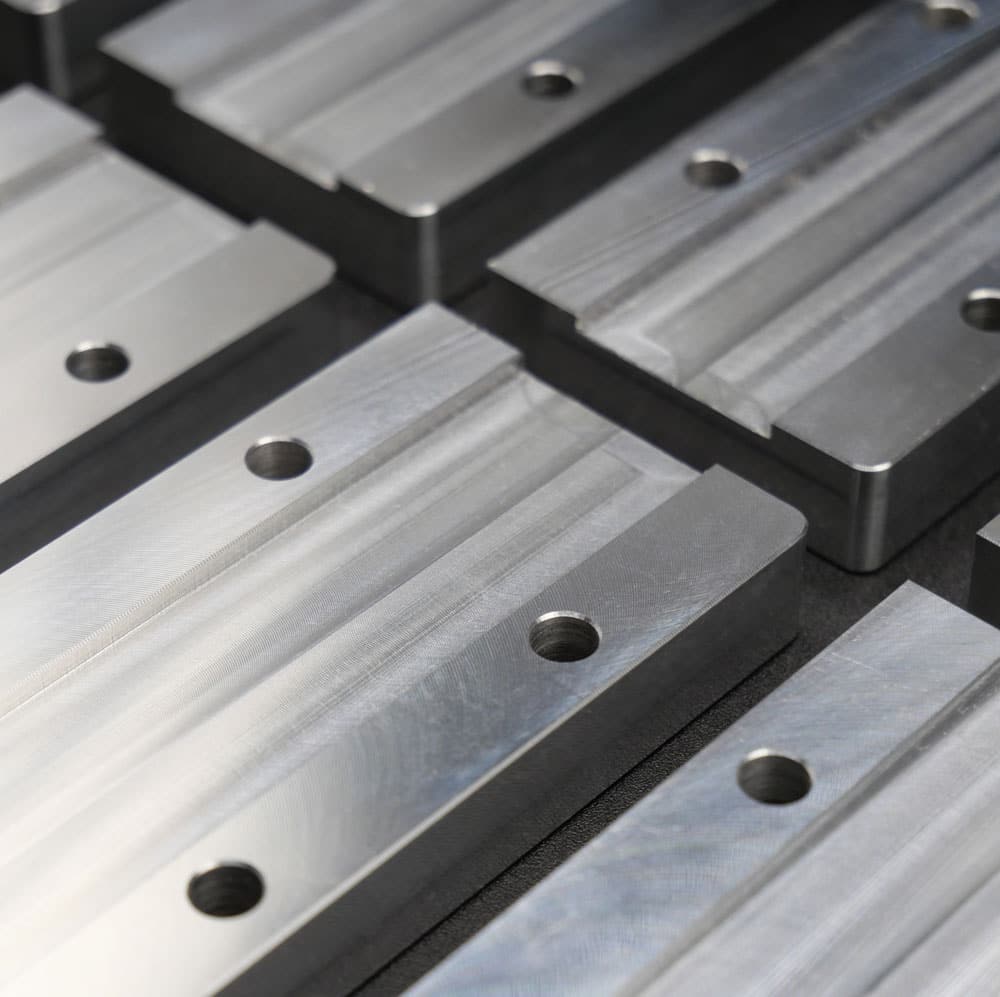

From aerospace to automotive, from mechanical engineering to defence, the different environments in which industrial sectors operate are all highly demanding in terms of precision. Whether it’s for the manufacture of prototypes, tools or final parts, each application must meet very precise specifications.

In this article, we present a way of obtaining precise parts quickly and at a lower cost, thanks to hybrid 3D printers and their precision.

Context: requirements and precision

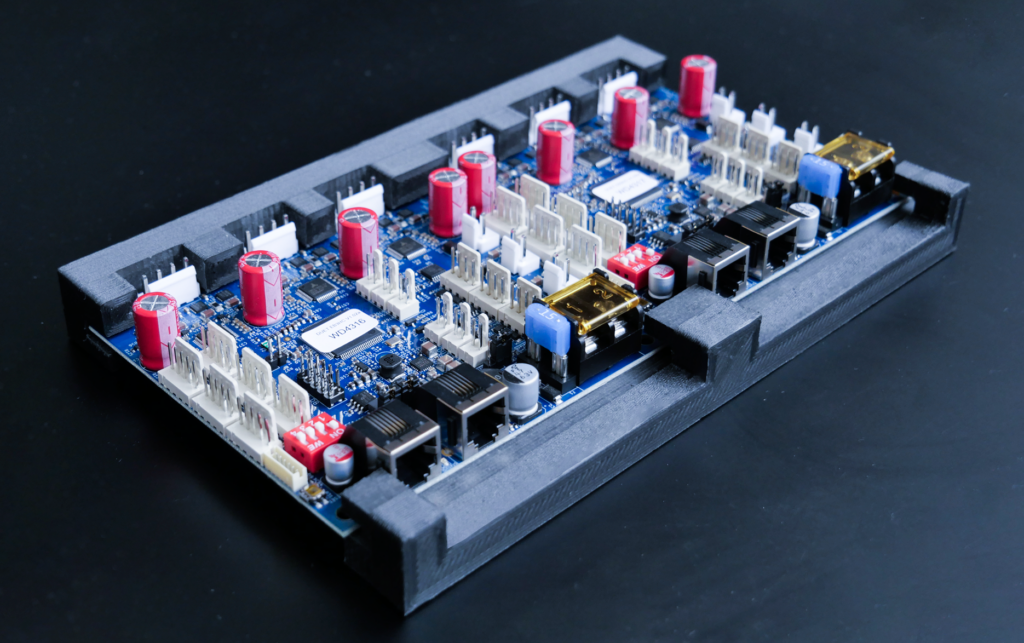

The part we’re showing you today was produced by one of our customers using the LUCY 300Y hybrid 3D printer. The customer wanted to obtain a support tool for a test tray holding several electronic boards.

This tooling had to meet several requirements:

- It had to be precise in order to meet the needs of holding the electronic boards and not damage them, given their fragility.

- It had to be able to withstand electronic discharges so as not to burn the boards, but also to ensure maximum user safety.

- Be made to measure to adapt to each test bench, but also to the electronic boards.

- Be developed and manufactured as quickly as possible to meet the demanding needs of industry.

Issues

Our customer initially thought of using a subcontractor to produce the part by complete machining from a blank, but the flexibility and lead times did not meet their requirements.

Solution: hybrid 3D printing

Tailor-made

Accuracy down to ±0.05mm

Finishes down to 0.3µm

Flexibility

Speed

Antistatic

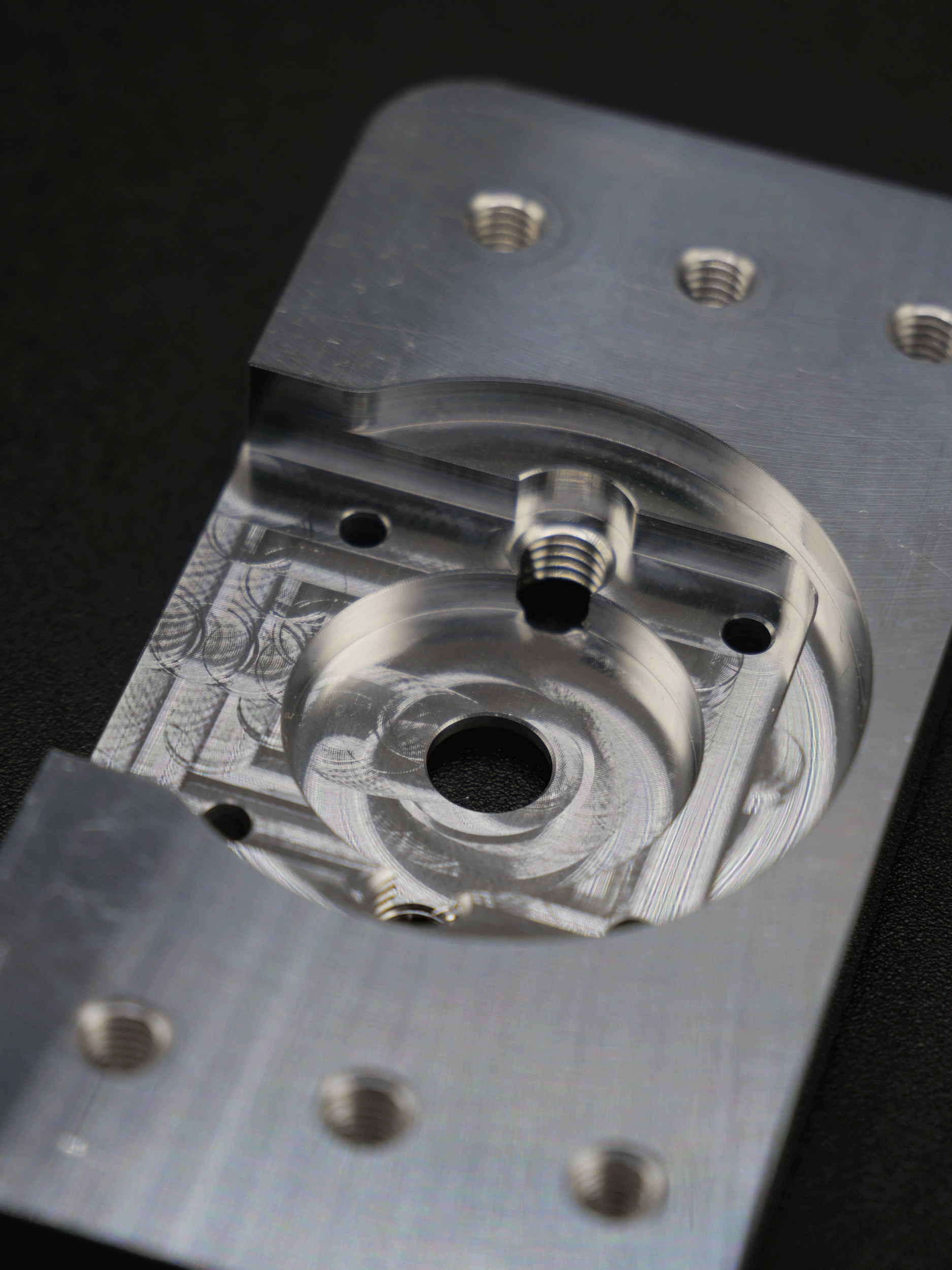

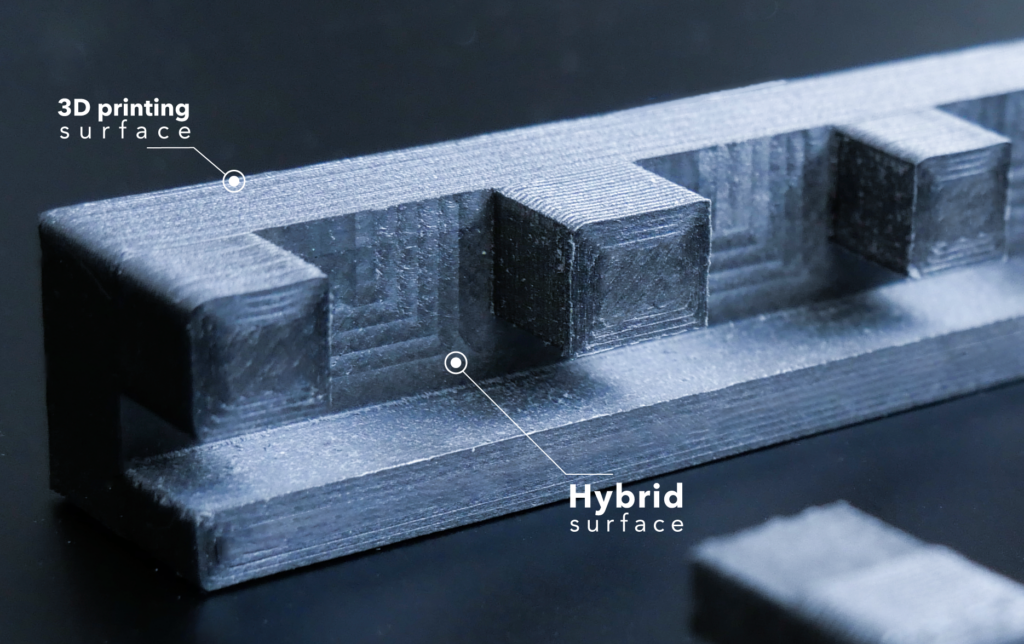

Our customer therefore acquired a LUCY 300Y, a 3D printer that combines 3D printing and machining simultaneously. This machine makes it possible to achieve a high level of precision on a part by customising the 3D printing and finishing the machining.

For this industrial customer, this hybrid solution makes it possible to :

- Produce a directly customised support to suit their needs.

- Achieve precise dimensional tolerances (down to ±0.05mm) to suit test benches and electronic boards.

- Fine surface finishes (down to 0.3µm) to avoid damage to electronic boards.

- Flexibility in the event of last-minute changes throughout the manufacturing process.

- Obtain parts quickly and cost-effectively.

- Use ESD raw materials (PETG ESD, ABS ESD, etc.) to resist electrostatic discharges.

The acquisition of a LUCY 300Y precision hybrid 3D printer offered our industrial customer several advantages over other manufacturing solutions:

10x

more accurate than FFF/FDM/FGF 3D printing

79%

savings compared with outsourcing

5

days ahead of subcontractors

If you’d like to find out more about hybrid 3D printing and our precision 3D printers, go straight to the LUCY 300Y page.

usinage pièce métal Machining: metal parts machined in less than 1 hour? In a constantly evolving industrial environment, machine manufacturers are constantly …

Your industrial tools at your fingertips In a constantly evolving industrial environment, controlling the production of tooling is a key issue for …