Is repeatability a guarantee of quality and performance in 3D printing?

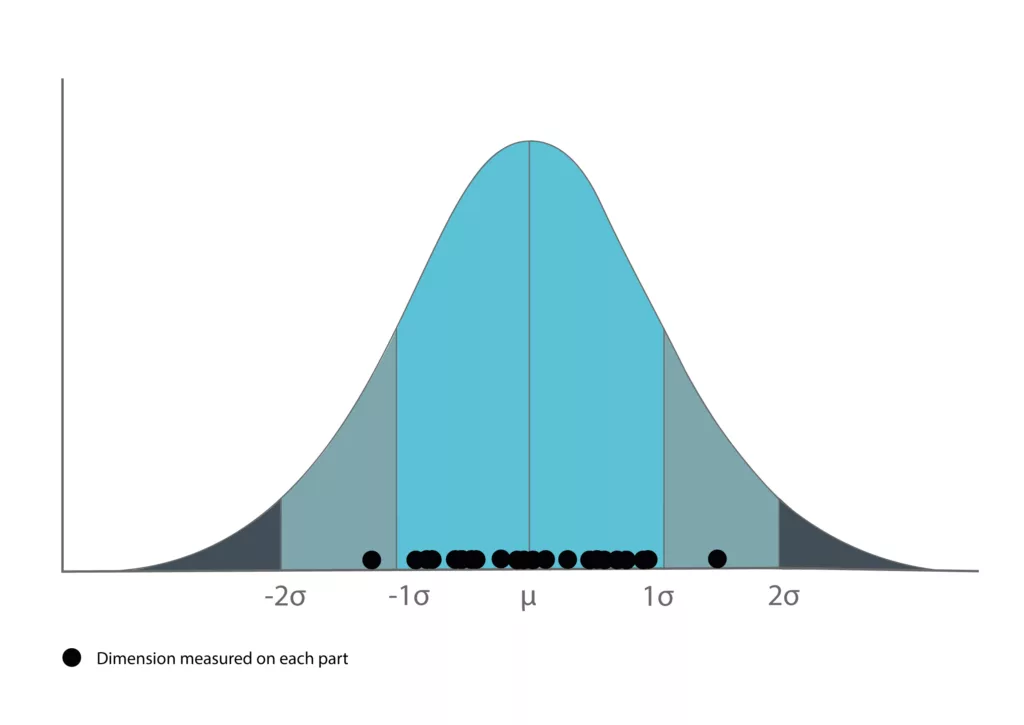

Repeatability is a fundamental concept in many fields, particularly engineering and production. It quantifies the ability of a system or process to reproduce consistent results under identical conditions. In other words, repeatability indicates the extent to which a measurement can be expected to give the same result if carried out several times.

In 3D printing, repeatability is characterised by a 3D printer’s ability to manufacture parts that are as identical and accurate as possible from one part to the next. Repeatability must enable identical dimensions to be achieved on each copy. However, the same measurement on two different parts is never equal, so we talk about standard deviation (the lower the standard deviation between several parts, the more repeatable the 3D printer).

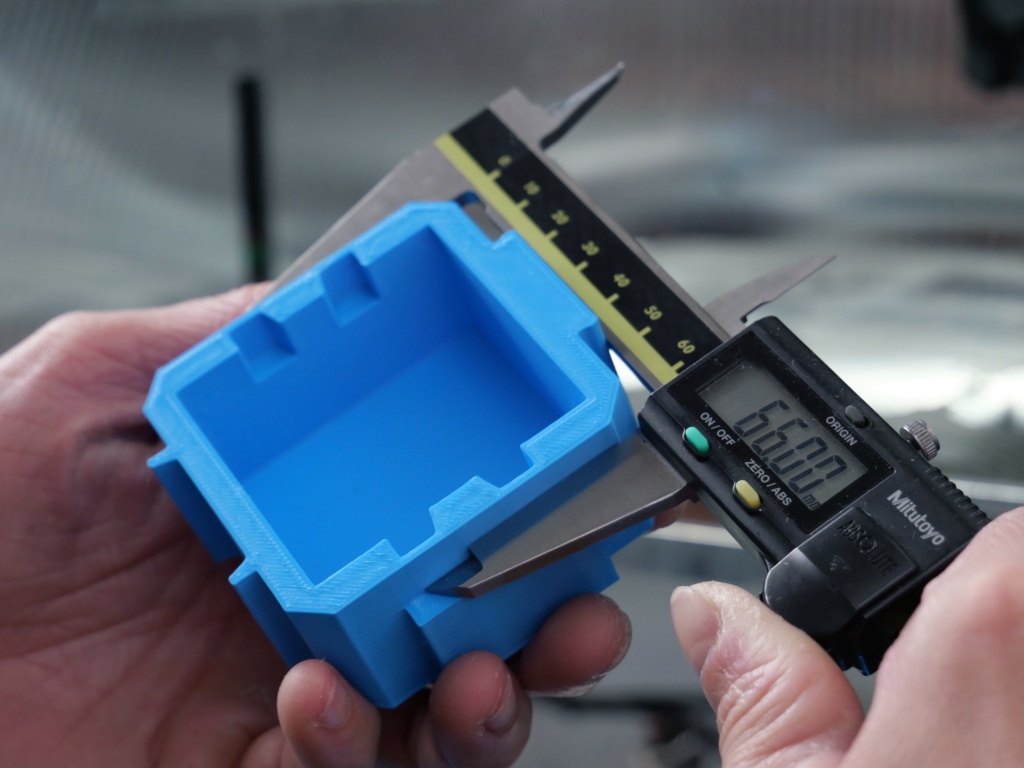

As for precision, this is achieved by complying with dimensional tolerances, i.e. the dimensions measured must be within a given range (e.g. a dimension must be accurate to within ±0.5mm). It is therefore important to measure the dimensions of each part manufactured in order to determine the repeatability and accuracy of a 3D printer.

This article will present a concrete case study to illustrate the benefits of repeatability in 3D printing.

Context

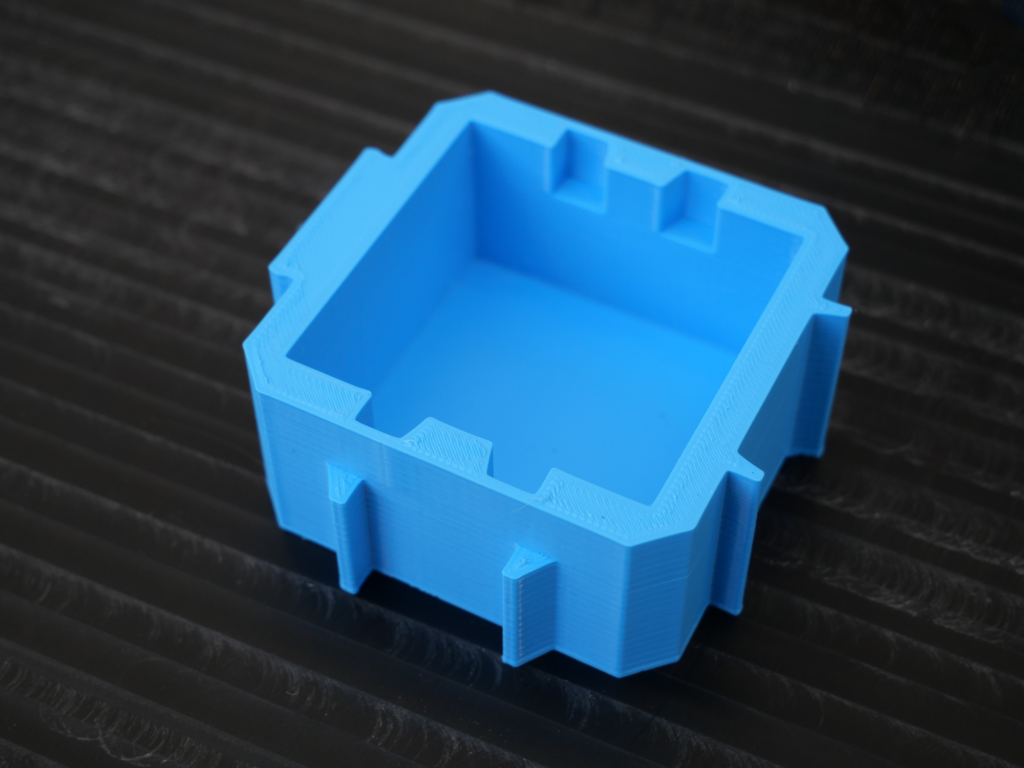

The parts presented in this case study come from the factory of one of our customers who has an ANA, the IDEX industrial 3D printer. The customer, who works in the food industry, has machines that he maintains himself.

Faced with the need to replace switch boxes, the manufacturer no longer had any spare parts. The company that used to make these boxes had stopped producing them, and they were no longer available on the market.

In order to avoid a lengthy production stoppage due to machine maintenance and the missing boxes, our industrial customer had to find a solution to urgently produce several copies of these parts.

Goals

The production of these parts therefore had to meet a number of requirements:

- A high level of repeatability, since each of the parts had to be reproduced as identically as possible to fit each engine,

- Respect dimensional tolerances,

- To be manufactured as quickly as possible.

Implementation and results

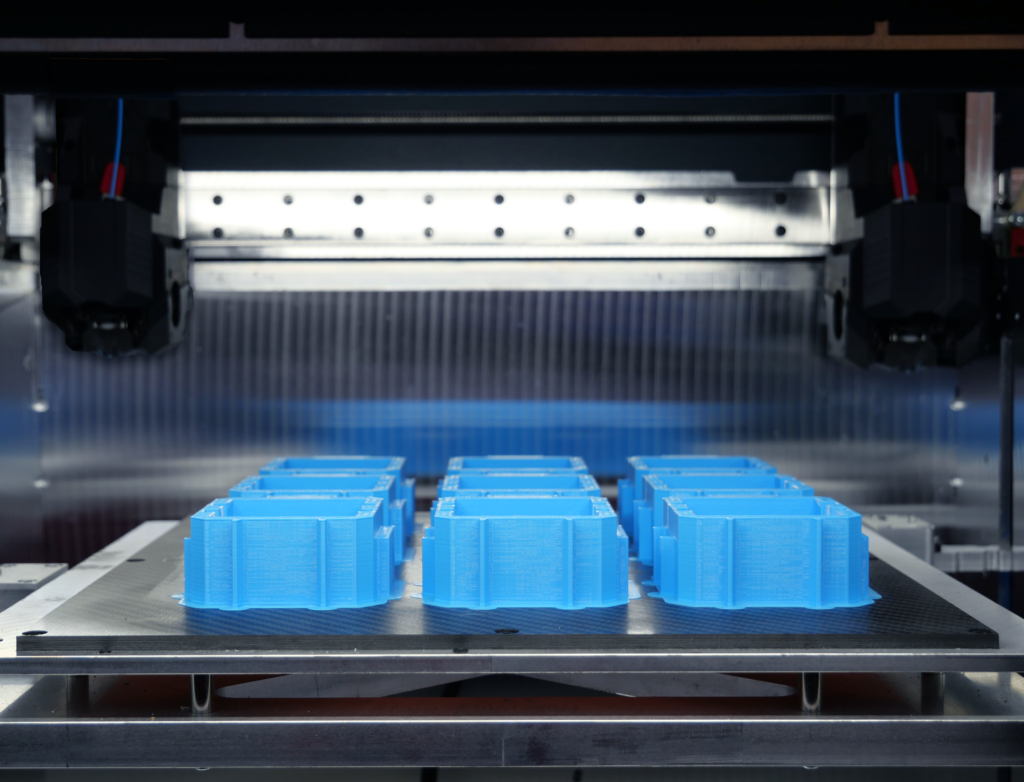

Equipped with an ANA 300X, the IDEX 3D printer, the manufacturer used this machine to meet its objectives for the production of these enclosures.

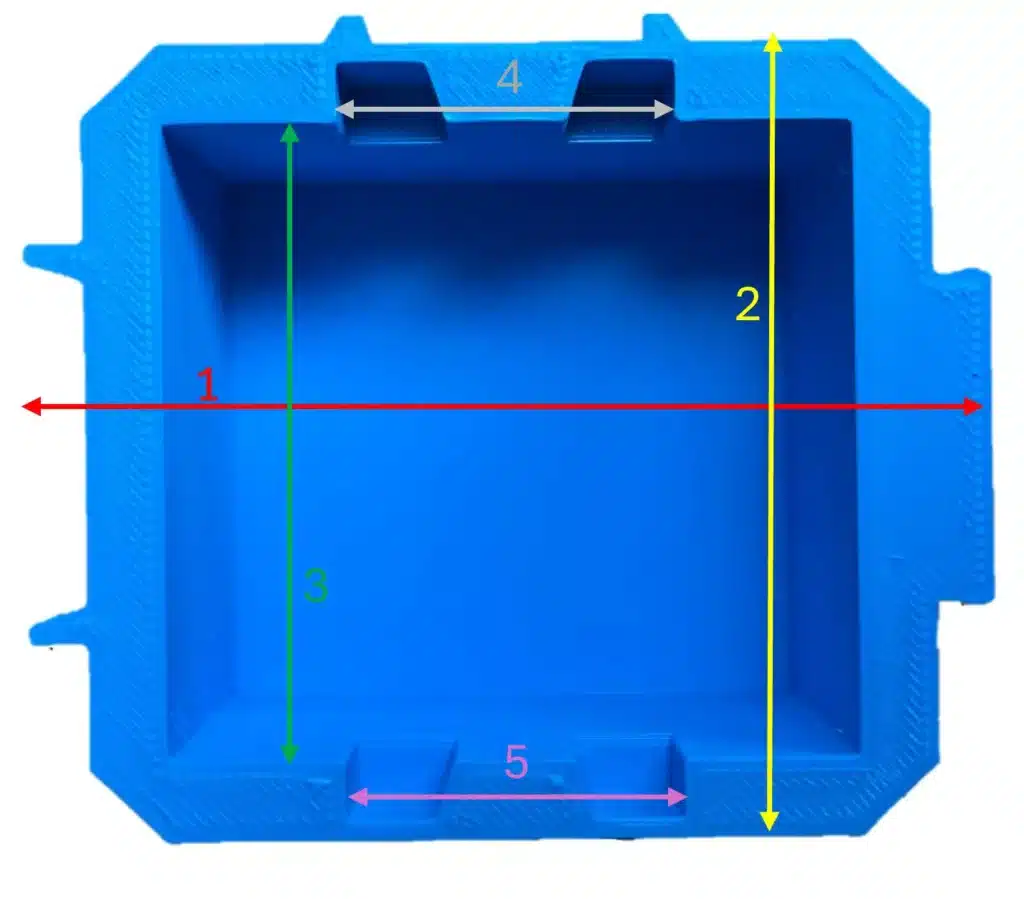

The part was produced in series, for a total of 43 units. 5 dimensions were analysed on the different parts, as shown in the photo below. Each dimension refers to a dimensional tolerance that must be respected.

The results of the 3D printed parts are as follows:

- The average standard deviation is equal to 0.047mm.

- The average precision is equal to 0.150mm.

- The average manufacturing time for a batch of 9 parts is 28 hours, or 3 hours 06 minutes per part.

Conclusion

Thanks to the ANA 300X, an IDEX 3D printer with two independent extruders, the customer was able to produce all these enclosures, meeting all the objectives.

The adoption of this 3D printing solution has enabled it to achieve :

- Repeatability of ±0.05mm on all the parts,

- Accuracy of ±0.15mm,

- 2x faster production, thanks to the dual extruder, which can manufacture parts simultaneously at speeds of up to 90mm³/s,

- Significant cost savings thanks to the time saved,

- Use of raw materials that meet industrial requirements (TPU, PLA, PETG CF, PA6 CF, ABS CF, etc.).

By opting for ANA 300X, our customer was able to benefit from high repeatability in 3D printing. As a result, he was able to produce parts in series that were as identical and precise as possible.

usinage pièce métal Machining: metal parts machined in less than 1 hour? In a constantly evolving industrial environment, machine manufacturers are constantly …

Your industrial tools at your fingertips In a constantly evolving industrial environment, controlling the production of tooling is a key issue for …