usinage pièce métal

Machining: metal parts machined in less than 1 hour?

In a constantly evolving industrial environment, machine manufacturers are constantly seeking to optimize their production processes to gain in efficiency, flexibility and competitiveness. Between increasing production rates, controlling costs and improving quality, the challenges are numerous, particularly in terms of metal part machining, and require solutions adapted to the specific requirements of each sector. Technological innovation plays a key role here, providing new approaches to rethinking part manufacturing and optimizing production methods.

Context

Our customer, a manufacturer of special machines for the pharmaceutical industry, was looking for an innovative solution to improve the design and production of metal machined parts for its equipment. Faced with stringent requirements in terms of precision, quality and compliance with pharmaceutical standards, it wanted to adopt advanced technologies to optimize its manufacturing methods and enhance the reliability of its machines.

Aims

To meet its needs, the company had several objectives:

- Increase production capacity to meet growing demand while maintaining consistent quality. This involved optimizing manufacturing methods, using innovative technologies to speed up production without compromising part precision and reliability.

- By internalizing the various manufacturing stages, the company wanted to gain greater autonomy and responsiveness. This approach made it possible to rapidly adapt production to specific customer requirements, reduce dependence on external suppliers, and improve quality control at every stage of the process.

- The optimization of production flows and the implementation of high-performance technological solutions were aimed at shortening the time needed to manufacture parts, while reducing costs linked to logistics and subcontracting operations. By improving overall process efficiency, the company was able to offer more competitive products, better adapted to the constraints of the pharmaceutical sector.

Achievements and results

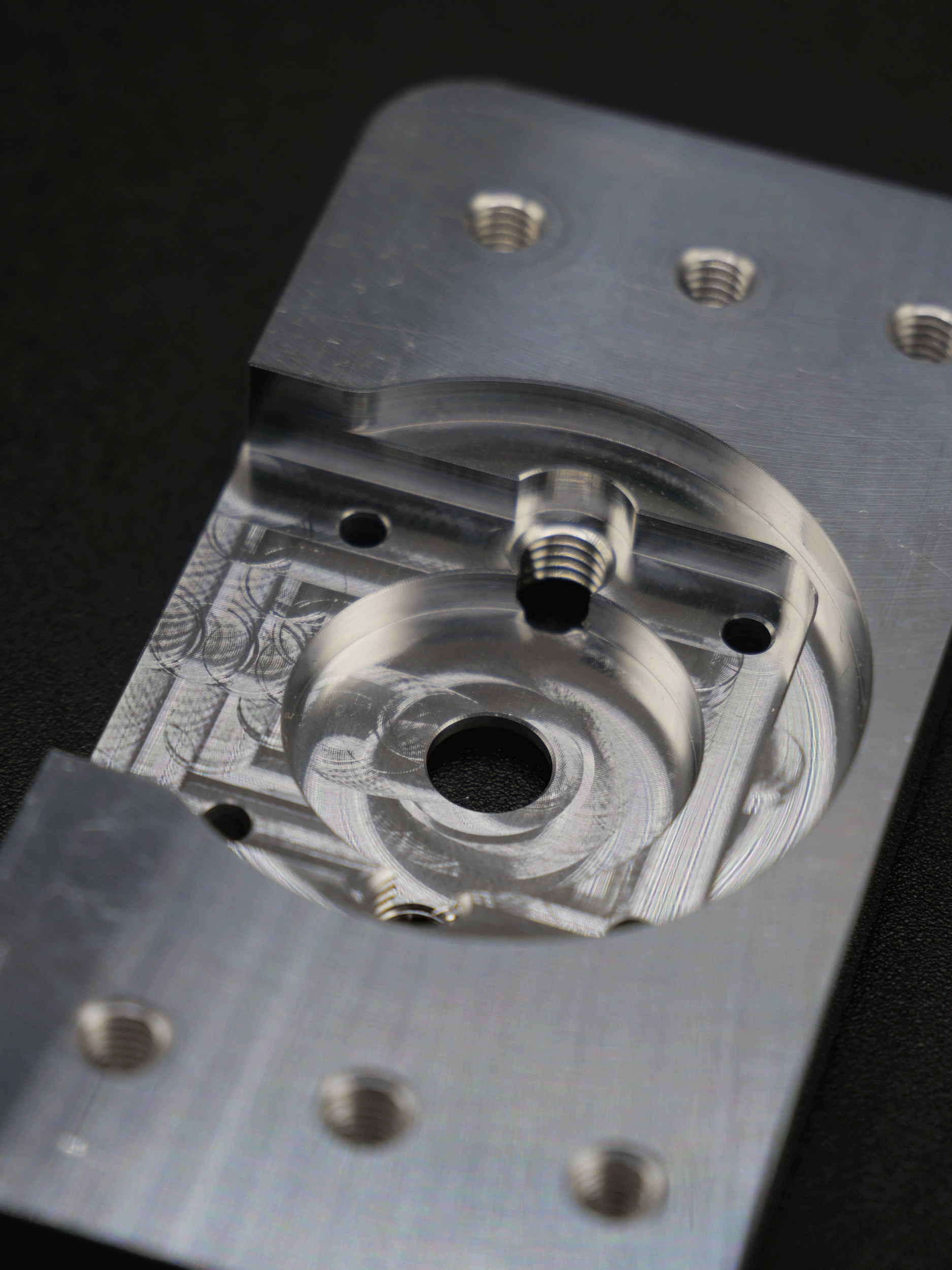

To meet its challenges, the company decided to internalize the manufacture of its parts by equipping itself with the EVA500, a compact multi-process machine combining machining and 3D printing. Through the mass-produced machined parts we present here, the company has benefited from several advantages:

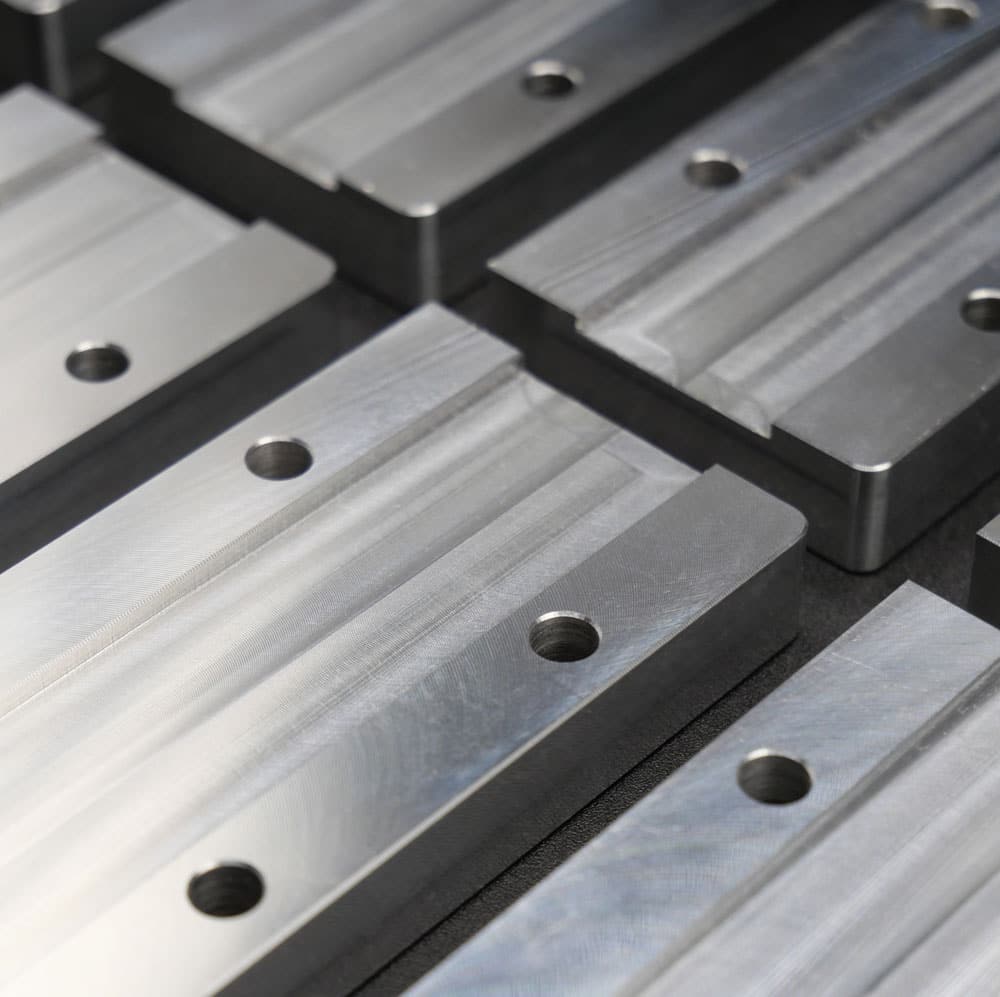

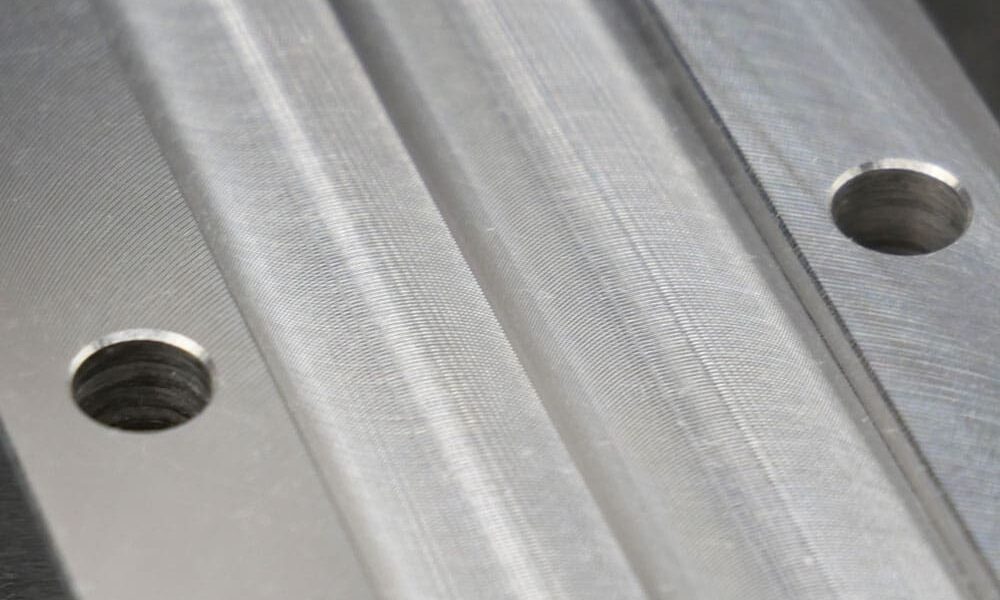

- This structural part was produced using 2D machining, a manufacturing process that involves cutting or drilling a material along two axes (X and Y). Programming 2D machining is fast and intuitive, facilitating production without the need for complex phase changes. Thanks to simplified clamping, part stability is ensured throughout the process, guaranteeing high precision with an integrated reference surface and dimensional tolerances controlled to ±0.05mm.

- The EVA range stands out for its ability to work with a variety of metals, offering optimum flexibility according to project requirements. Here, 5083 aluminum was chosen for its excellent strength/lightness ratio, essential for this customer’s industrial applications. Other materials such as copper and brass can also be used. Copper is ideal for its thermal and electrical conductivity properties, while brass offers high wear resistance and ease of machining.

- Thanks to EVA500’s mass production capability, the special machine manufacturer’s part could be made in several copies simultaneously. The part’s reference dimensions were 90mm x 40mm x 15mm, so it was possible to manufacture up to 10 units at the same time on the machine, with a manufacturing volume of 500mm x 500mm x 500mm. With a manufacturing time of just 4 minutes per part, this approach optimized productivity, reducing total production time to just 40 minutes for 10 parts manufactured simultaneously.

- Internalizing the production process considerably reduced costs compared with outsourcing, offering an economical alternative at just €8.5 per part, for total savings of €12,750 per year.

- The EVA500’s 2-in-1 solution provides greater flexibility for the manufacture of parts for special machines, by switching from machining to 3D printing in less than 1 minute on the same machine, which also requires the manufacture of polymer parts (ABS, PETG, TPU, etc.). This versatility also benefits companies, enabling them to respond to the widest possible range of applications.

Summary of the manufacturing process :

Faced with the growing challenges of industry, the adoption of innovative technologies enables companies to stand out from the crowd by optimizing and internalizing their manufacturing processes. By integrating flexible, high-performance solutions, it becomes possible to respond more effectively to the requirements of metal part machining in terms of quality, precision and deadlines, while keeping costs under control. Innovation, whether in machining or 3D printing, is thus a strategic lever for companies wishing to improve their competitiveness and reinforce their autonomy.

Your industrial tools at your fingertips In a constantly evolving industrial environment, controlling the production of tooling is a key issue for …

3D printing: new allies for watch manufacturers? The watchmaking industry is renowned for its demand for precision. Every stage of the manufacturing …