Large-format 3D printers: for what applications?

3D printers are now part of the industrial landscape and are powerful tools in the manufacture of industrial parts. But different industrial sectors face demanding technical challenges and need tailor-made solutions capable of meeting certain constraints. Industrial applications sometimes depend on a large-scale environment and require large-format manufacturing. Large-format 3D printers are capable of producing parts measuring up to 1 metre in this case, opening up new perspectives.

With its ability to optimise manufacturing processes, large-format 3D printing is now an essential lever for companies seeking to improve their performance.

Context

One of Namma’s customers, specialising in the agri-food sector, needed grippers to equip the robotic arms in its factory. These tools had to be capable of handling different ranges of bottles, with varying sizes and weights. This diversity required a customised, large-format solution capable of meeting the specific constraints of its production process.

Goals

Each gripper had to meet very specific requirements:

- Each model had to be tailor-made to adapt precisely to the different types of bottle necks. This ensured stable and safe handling, even when bottles varied in shape or size.

- The grippers had to be large enough to handle several bottles at a time. This capability was essential to improve productivity by reducing the number of movements required to handle batches.

- It was crucial that the proposed solution optimised the cost of manufacturing the grippers, while limiting the time required to produce them.

Implementation and results

Thanks to EVA, the large-format, multi-process 3D printer, this customer can now produce parts perfectly tailored to his needs. This solution offers several advantages:

- EVA enables each gripper to be customised to suit a variety of bottleneck sizes. What’s more, this customisation flexibility is a major advantage when launching a new product range, making adjustments quick and easy.

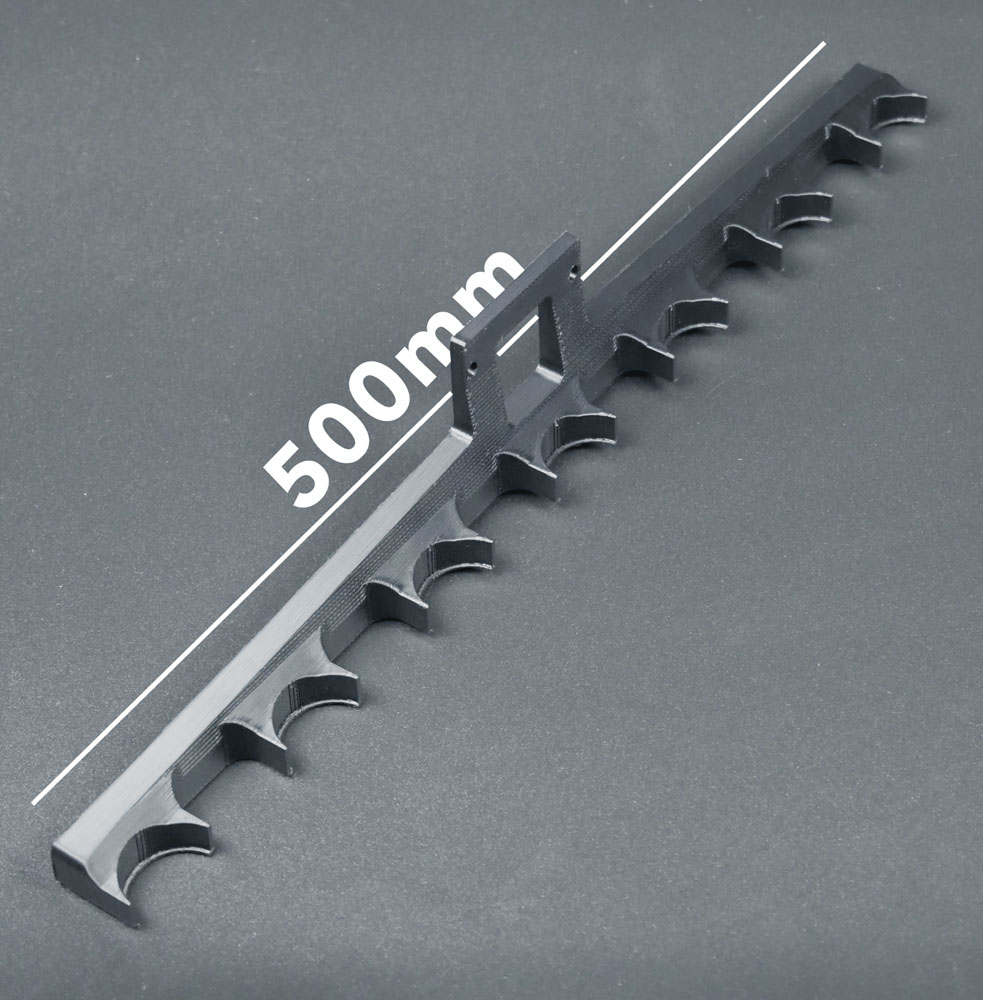

- The EVA 3D printer is capable of producing large format parts, up to 1000mm x 500mm x 500mm. This makes it possible to produce one-piece parts, without the need for assembly or gluing. For example, the gripper shown here measures 500mm, and is ready for use straight out of the machine.

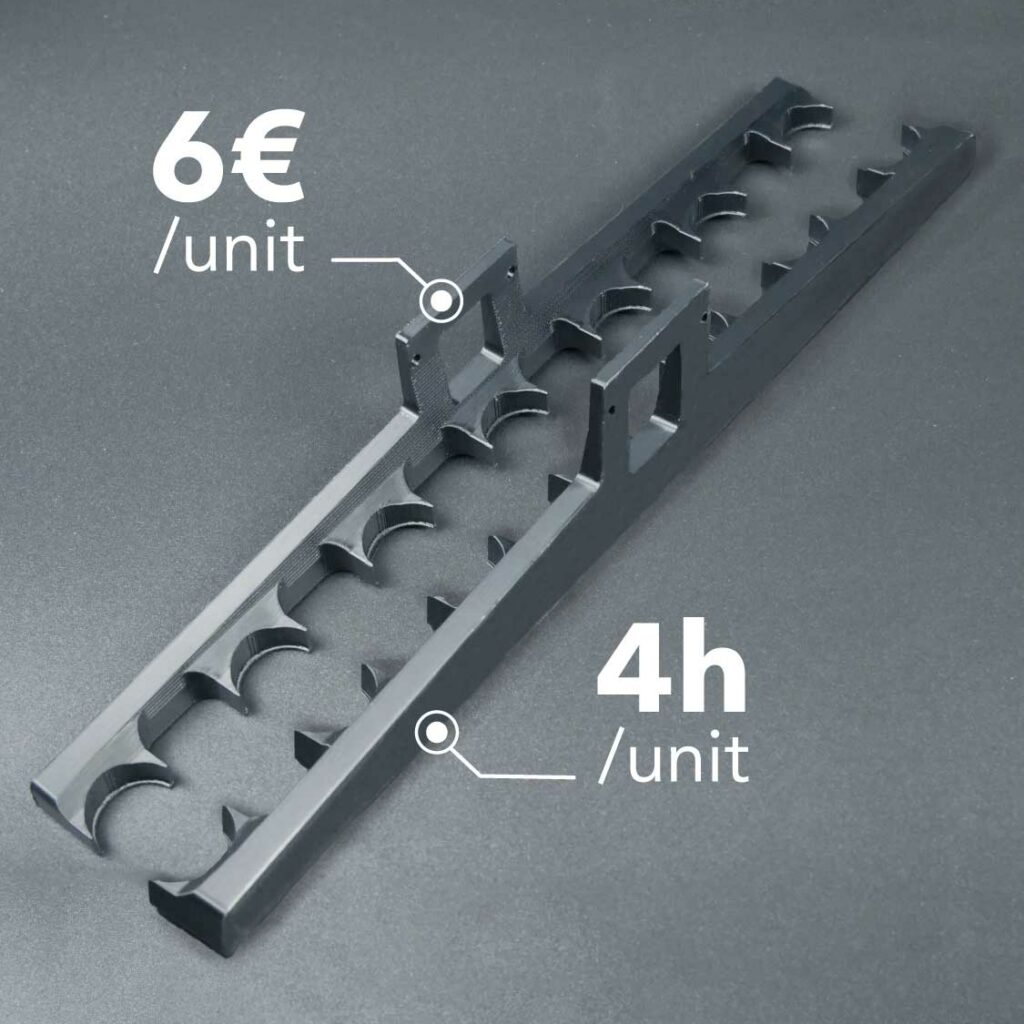

- By manufacturing its own parts on site, this customer has considerably reduced the supply chain. Each gripper is produced in just 4 hours, offering a speed that facilitates the management of industrial deadlines.

- By bringing tooling manufacture in-house, each part is produced completely independently, using only the quantity of material that is strictly necessary, thus avoiding unnecessary costs. The cost of manufacturing parts is now €6 per unit.

Conclusion

Large-format 3D printers are revolutionising manufacturing processes by making it possible to produce large parts that are perfectly suited to industrial needs. By reducing assembly stages and optimising production times, they offer companies unrivalled flexibility. These machines push back the boundaries of industrial innovation and open up new perspectives for ever more ambitious applications.

usinage pièce métal Machining: metal parts machined in less than 1 hour? In a constantly evolving industrial environment, machine manufacturers are constantly …

Your industrial tools at your fingertips In a constantly evolving industrial environment, controlling the production of tooling is a key issue for …