Your industrial tools at your fingertips

In a constantly evolving industrial environment, controlling the production of tooling is a key issue for many companies. Between quality requirements, part availability and adaptability to production needs, it is becoming essential to rethink manufacturing methods in order to remain competitive. The manufacturing processes for industrial tools must be precise, efficient and capable of adapting quickly to fluctuations in demand. Against this backdrop of constant efforts to improve efficiency, it is crucial to assess the tools and technologies available to meet these challenges while maintaining impeccable quality.

Context

As a major player in the aerospace sector, the company faced a major challenge: with demand constantly on the increase, it was essential to rethink the organisation in order to manufacture parts more efficiently, designed by the methods department, and make them available more quickly to better meet production needs.

Goals

To meet its production challenges and keep pace with its growth, the company wanted to :

- With internal demand from the production department rising sharply, it became essential to increase manufacturing capacity to avoid any bottlenecks. The company needed to ensure that it could produce more industrial tooling in less time, while maintaining the required level of quality. But it also needed to be able to supply the bespoke parts that the production department required.

- The group wanted to reduce its dependence on external suppliers and gain better control over its lead times. This increased autonomy should enable it to respond more quickly to the needs of the production department, while adapting its manufacturing to priorities and urgent requirements.

- Speed of execution and profitability were key issues in this process. The aim was therefore to find a solution that would enable production to be carried out faster and more economically.

Implementation and results

To meet its production challenges, this company decided to bring the manufacture of its tooling in-house by equipping itself with EVA, a multi-process machine combining machining and 3D printing. Through the machined tooling we present here, the company has benefited from a number of advantages:

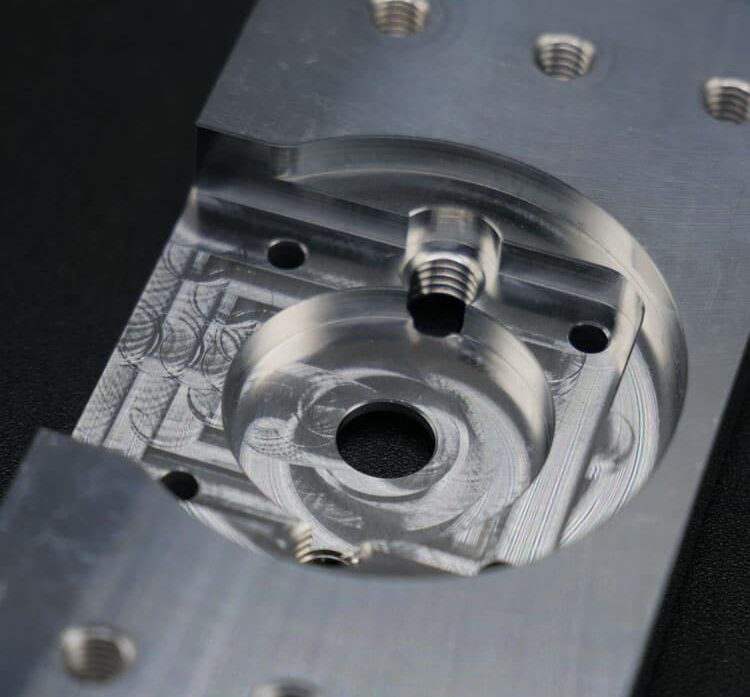

- By equipping itself with EVA, the company has benefited from not one, but 2 processes, with the possibility of manufacturing 3D parts in 1 machine thanks to several tool heads. One of EVA’s main assets is its ability to switch from traditional machining to 3D printing in less than a minute. This dual functionality opens up new possibilities for the manufacture of customised tooling with complex shapes. In addition to metal machining, the company can now produce polymer components through additive manufacturing, using materials such as ABS, PETG and TPU. This diversity of materials means we can develop technical solutions tailored to each industrial application.

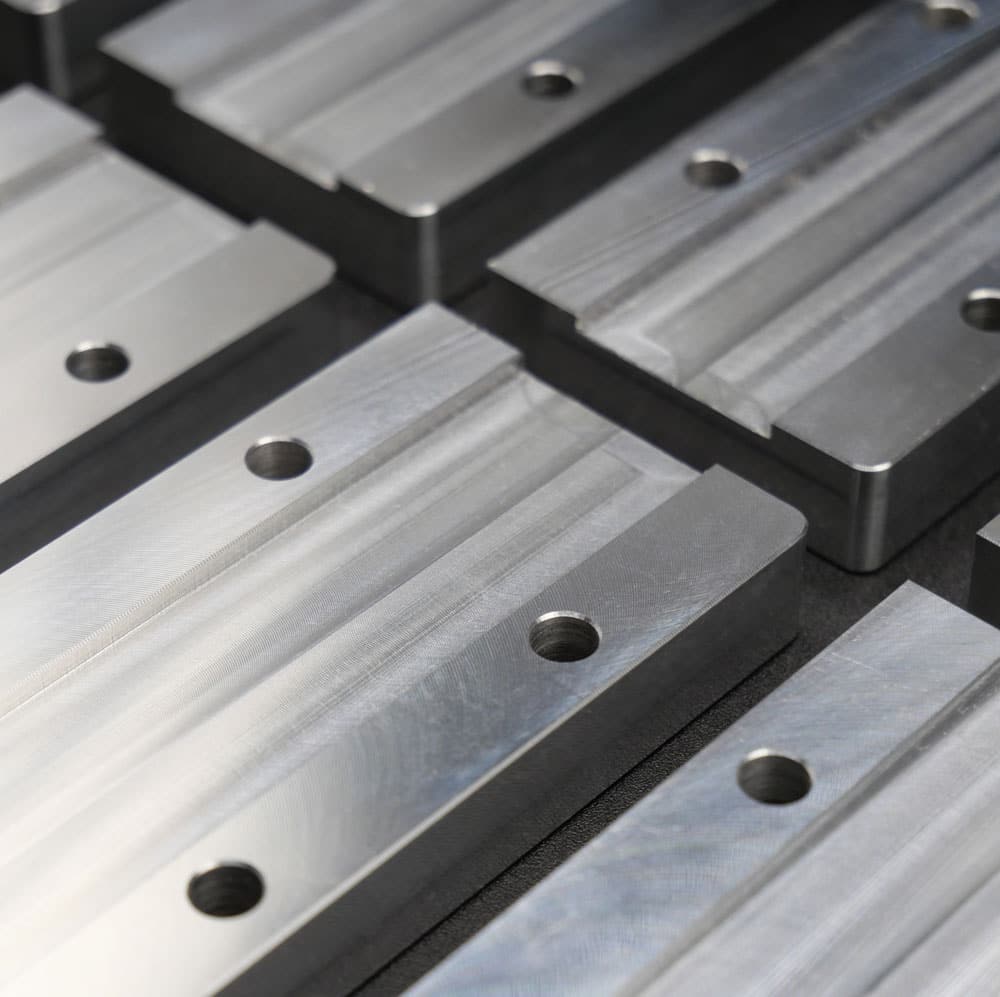

- With a manufacturing volume of up to 1000mm x 500mm x 500mm, EVA enables the company to produce large machined parts, either in monobloc or in series, from a raw material of filament or granulate. This is the case with the example part, mass-produced thanks to the volume offered by EVA. This has increased the company’s flexibility, which is invaluable when it comes to designing this high-performance industrial tools. Parts can now be machined directly on site, in a single operation, guaranteeing greater precision and smoother integration into production processes.

- Machining industrial tools often involves the use of specific materials capable of withstanding the mechanical, thermal or chemical constraints imposed by the production environment. The part shown here is made from 5083 aluminium, a lightweight, mechanically resistant and easily recyclable material. EVA offers the possibility of working with different metals, such as aluminium, copper or brass, to meet the varied requirements of tooling.

- By bringing the manufacture of its tooling in-house, the company has been able to cut its lead times and production costs by a factor of 3. The company can now produce directly in-house, enabling it to reduce tooling lead times. The industrial tooling shown here was manufactured in 15 minutes at a cost of €19/piece. Prior to the acquisition of EVA, each new request for industrial tools involved internal and external processes, with lengthy purchasing, negotiation and supply procedures, as well as exchanges with subcontractors.

- As well as technical performance, the choice of EVA is also part of an approach based on proximity and long-term support. Designed and manufactured in France, the company benefits from comprehensive post-purchase support, including installation, team training and responsive technical support. As a result, companies can be sure that they will be able to make full use of the machine’s capabilities, with the support of a contact person who can help them as their needs evolve.

The company now manufactures a wide range of tools, as shown here, using the machining process offered by EVA, the multi-process machine. This project demonstrates that the adoption of innovative technologies can transform internal processes, offering greater responsiveness, cost control and flexibility in the face of ever more pressing demands in the manufacture of industrial tooling. By bringing its manufacturing processes in-house, the company has boosted its competitiveness and its ability to adapt quickly to market challenges.

usinage pièce métal Machining: metal parts machined in less than 1 hour? In a constantly evolving industrial environment, machine manufacturers are constantly …

3D printing: new allies for watch manufacturers? The watchmaking industry is renowned for its demand for precision. Every stage of the manufacturing …