Materials compatible with EVA

Industrial grade additive and subtractive manufacturing materials designed for Namma machines.

Open environment

EVA is compatible with both N-mat (Namma’s materials) and materials from other suppliers.

the process used

3D Printing

Fused deposition modeling

Additive manufacturing is the best way to go from idea to prototype quickly and cheaply.

Non-exhaustive list.

Uses: Functional prototypes, industrial moulding, general purpose parts

Advantages: impact resistant, durable, heat resistant

Uses: parts subject to high loads

Advantages: mechanical strength, heat resistant

Uses: PCB holders, electrical boxes

Advantages: impact resistant, heat resistant

Uses: ideal for outdoor parts

Advantages: UV resistant, weather resistant, high mechanical strength

Uses: print media

Advantages: soluble

Applications: tooling, automotive, functional parts, medical

Advantages: high heat resistance (190°C), impact, abrasion and friction resistance, corrosion and chemical resistance

Uses: protective housings, functional prototyping, structural components

Advantages: high mechanical strength, high thermal resistance, historically used in industry

Uses: food contact parts (molds, containers), electrical components, medical devices

Advantages: waterproof, translucent, food safe, electrically insulating, lightweight, easy to use

Uses: Mock-ups, design objects, model packaging, marketing

Advantages: Easy to print, rigid, biodegradable, biosourced

Uses: assembly parts, belts, hulls, protections

Advantages: flexible, impact resistant, tear resistant

the process used

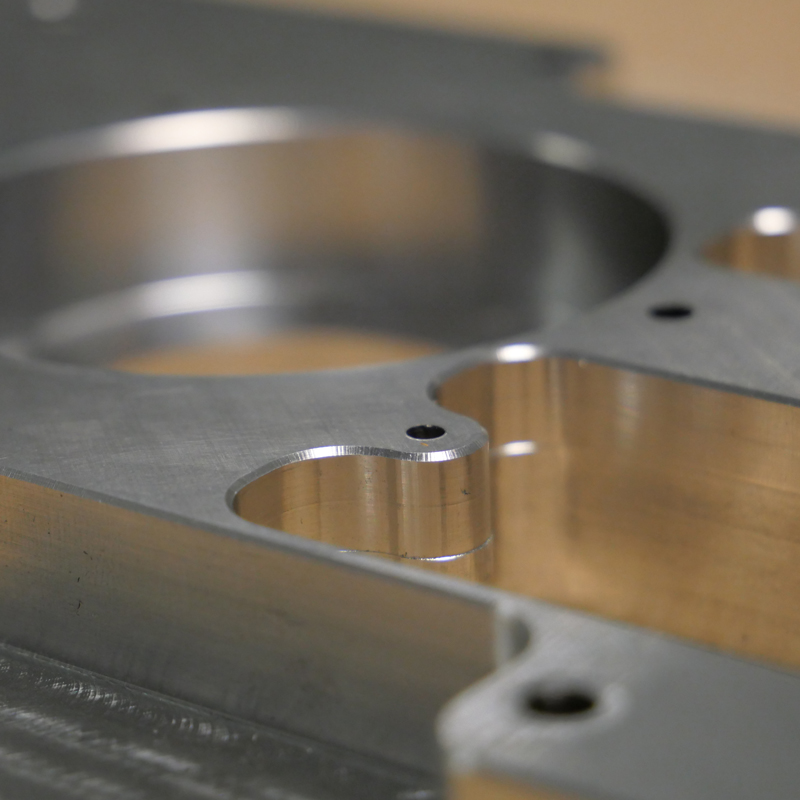

CNC Machining

3 axis / 3 continuous axis

CNC is used to work materials used in industry such as aluminium and to obtain durable and precise finished parts.

This list is not exhaustive.

Uses: tooling, structural components, aerospace, automotive

Advantages: mechanical, thermal and chemical resistance

Uses: structural parts, decoration

Advantages: renewable, ecological, aesthetic

Uses: structural parts, competitive sports, aeronautics, automotive,

Advantages: light, mechanical and thermal resistance, electrical and thermal conductor

Uses: shipbuilding, electronics, electrical, construction,

Advantages: electrical and thermal conductivity, corrosion resistance

Uses: depending on the material

Advantages: 3D printed parts with precise tolerances and correct surface finishes

Uses: jewellery, watches, locksmiths

Advantages: corrosion resistant, malleable, ductile

Uses: packaging, protection, storage blocks

Advantages: lightweight, high elastic deformation, shock absorbing

Uses: nuclear, aerospace, automotive, medical

Advantages: excellent mechanical, chemical and high temperature resistance, fire resistance

Uses: general engineering, machining martyr, insulator, gear wheel

Advantages: impact, tensile, fatigue, heat and dimensional stability

Uses: kitchen utensils, mechanical tools, contact between parts

Advantages: non-stick, thermal and chemical resistance

the process used

Laser cutting

UV Laser

Laser cutting allows the user to make precise and complex cuts. It also offers the possibility of making small details.

This list is not exhaustive.

Uses: POS, displays, conservatories, anti-COVID protection and separation

Advantages: transparent, recyclable, UV resistant

Uses: decorations, packaging, models,

Advantages: light, economical, recyclable and biodegradable

Uses: luxury, textile, saddlery, leather goods

Advantages: robust and durable

Uses: decoration, furniture industry

Advantages: isotropic, economical

Uses: packaging, protection, storage blocks

Advantages: lightweight, high elastic deformation, shock absorbing

Uses: guides, stencils, jigs

Advantages: economical, used on a large scale

Uses: filters, seals, templates

Advantages: flexible, non-woven

Uses: sealing component, wetsuit prototype

Advantages: thermal, hydrocarbon and weather resistance

Uses: sheaths, straps, handles

Advantages: elastic, waterproof

Uses: seal, mould

Advantages: elastic, waterproof, heat resistant

The process used

Laser engraving

UV Laser

Laser engraving offers the possibility of creating different 2D shapes on a part to inscribe a serial number, a tooling number or a pattern.

This list is not exhaustive.

Uses: serial number, tool marking, traceability

Advantages: mechanical, thermal and chemical resistance

Uses: decorations, packaging, models,

Advantages: light, economical, recyclable and biodegradable

Uses: luxury, textile, saddlery, leather goods

Advantages: robust and durable

Uses: decoration, furniture industry

Advantages: isotropic, economical

Uses: packaging, protection, storage blocks

Advantages: lightweight, high elastic deformation, shock absorbing

Uses: guides, stencils, jigs

Advantages: economical, used on a large scale

Uses: filters, component seal, jigs

Advantages: flexible, non-woven

Uses: component seal, prototype wetsuit

Advantages: thermal, hydrocarbon and weather resistance

Uses: decoration

Advantages: aesthetic, mechanical resistance

Uses: serial number, traceability

Advantages: lightweight, mechanical strength

N-Mat : optimized materials for EVA

Namma has developed its own range of materials for EVA: N-Mat. By choosing N-Mat, you have access to tested and qualified printing profiles to succeed in every production. With the classic range and the technical range, use the materials adapted to each need.