CNC tool head

CNC11

The accessible tool-head

With the CNC11 tool head, you can machine a wide variety of parts. It offers the possibility of machining soft materials such as polymers, wood and derivatives.

Compact

The CNC11 is an ultra ergonomic tool head that meets your exceptional machining needs.

Complementary

Combine the CNC11 with the 3DF02 to produce accurate, low-cost hybrid parts. Machine the functional surfaces of 3D printed parts and achieve parts with smooth surface finishes and precise dimensional tolerances.

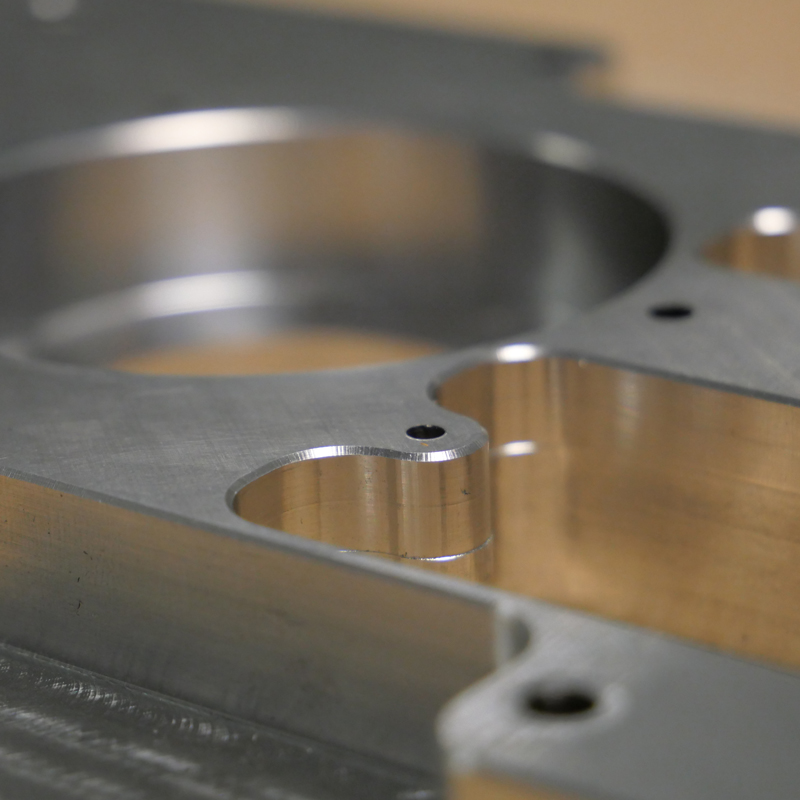

Precise parts with the CNC11

3D printed and machined part

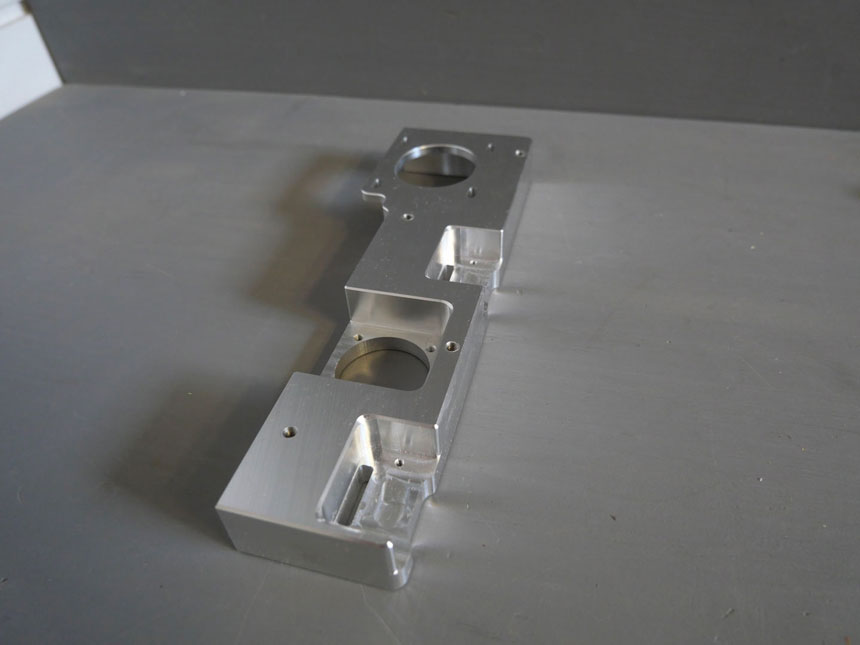

CNC22

The high-performance tool head

Step up a gear with the CNC22 tool head. A robust and powerful tool head for machining tough parts.

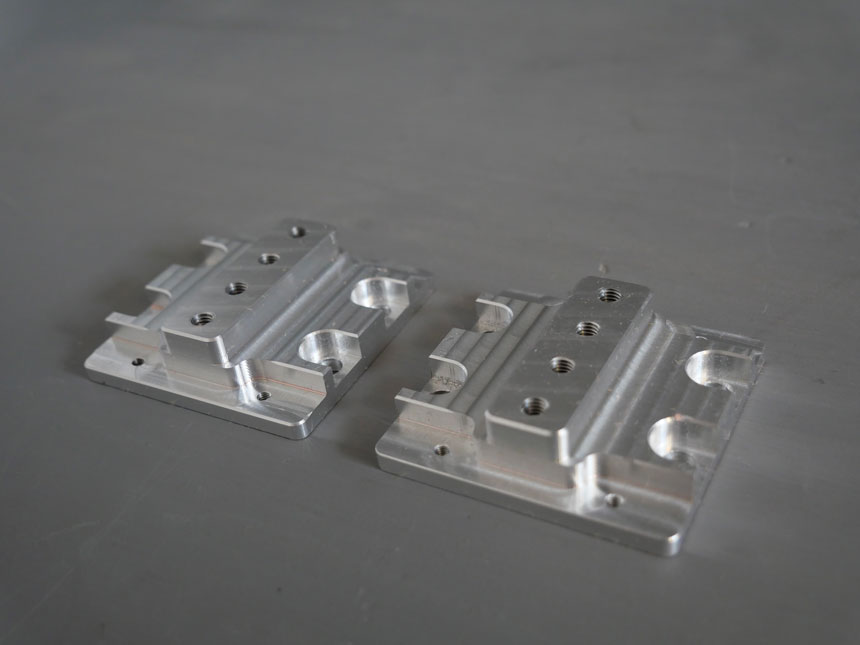

Quick tool changer

Reduce your cutting tool changeover times with HSK tapers. Quickly change machining phases thanks to automatic tool length measurements stored directly in N-play.

From metal to composites

Machine metals such as aluminum, brass or copper for long-lasting parts.

Production tooling

Structural holding parts

Configurations designed for intensive machining

Micro-lubrication system

Vacuum system for shavings

Cone tool changer

Water cooling of the spindle

Precise and robust parts

With machining in your shop, produce precise parts. The CNC22 allows you to produce a wide variety of metals for your prototypes, tooling and final parts.

Features

Tool heads for your applications

Compatible materials

the process used

CNC Machining

3 axis / 3 continuous axis

CNC is used to work materials used in industry such as aluminium and to obtain durable and precise finished parts.

This list is not exhaustive.

Uses: tooling, structural components, aerospace, automotive

Advantages: mechanical, thermal and chemical resistance

Uses: structural parts, decoration

Advantages: renewable, ecological, aesthetic

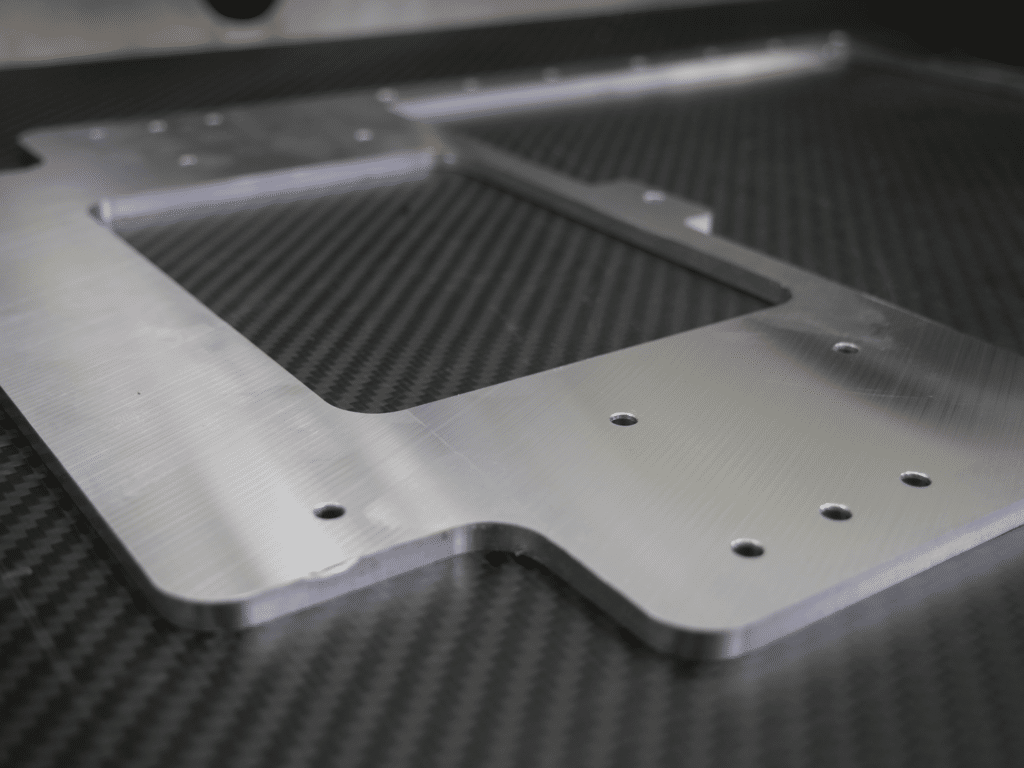

Uses: structural parts, competitive sports, aeronautics, automotive,

Advantages: light, mechanical and thermal resistance, electrical and thermal conductor

Uses: shipbuilding, electronics, electrical, construction,

Advantages: electrical and thermal conductivity, corrosion resistance

Uses: depending on the material

Advantages: 3D printed parts with precise tolerances and correct surface finishes

Uses: jewellery, watches, locksmiths

Advantages: corrosion resistant, malleable, ductile

Uses: packaging, protection, storage blocks

Advantages: lightweight, high elastic deformation, shock absorbing

Uses: nuclear, aerospace, automotive, medical

Advantages: excellent mechanical, chemical and high temperature resistance, fire resistance

Uses: general engineering, machining martyr, insulator, gear wheel

Advantages: impact, tensile, fatigue, heat and dimensional stability

Uses: kitchen utensils, mechanical tools, contact between parts

Advantages: non-stick, thermal and chemical resistance