3D printing: new allies for watch manufacturers?

The watchmaking industry is renowned for its demand for precision. Every stage of the manufacturing process is crucial, and every component plays a fundamental role in the quality and reliability of the watches produced. However, meeting these demands is not without its challenges. To ensure meticulous workmanship, the tools and processes used to manufacture and assemble watches must be adapted to precision work. These requirements call for manufacturing processes that are flexible, fast and capable of guaranteeing perfect homogeneity between the parts produced.

Today, many watch manufacturers and watchmakers are looking for innovative solutions to improve their production processes and achieve ever-better results. How is 3D printing being used by watch manufacturers?

Context

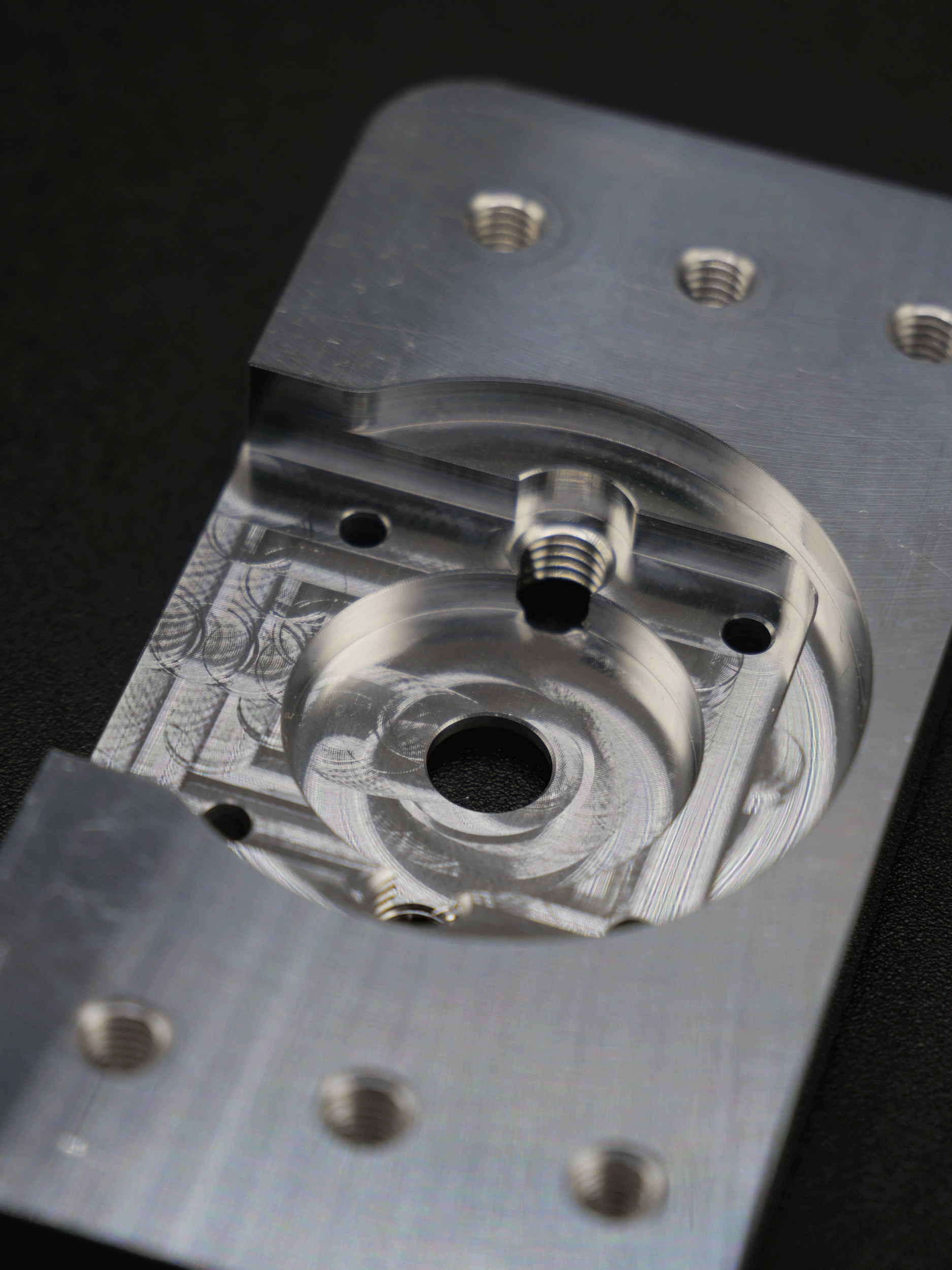

Specialising in the watchmaking industry, our client was looking for a solution to optimise its watch production. Its objective was to optimise its assembly supports for the assembly of different watch models.

Aims

- In the watchmaking industry, precision is a priority. It is essential to ensure that the supports produced match the dimensions of the watch dials. This means achieving a precise match between the models designed and the parts manufactured. This precision is central to facilitating the work of watch assemblers, who handle delicate components that require a high degree of stability.

- The customer wanted to be able to manufacture several supports for different watch models simultaneously. This allows each watchmaker to work on different watch models at the same time. This makes production faster and smoother, while ensuring the quality of each support is matched to the model.

- He also wanted faster processes to optimise production times, while maintaining high quality.

Achievements and results

IDEX 3D printing guarantees precision results of ±0.15mm, ensuring compliance with the dimensional tolerances of the drawings. This level of precision ensures that each part produced corresponds to the models in the drawings and fits each watch model. What’s more, repeatability is within ±0.05mm, enabling the model to be faithfully reproduced on all the parts produced, guaranteeing consistency with each new production run.

The integration of two independent extruders in the IDEX 3D printer also speeds up the manufacturing process, resulting in production that is twice as fast compared with conventional, professional 3D printers. In fact, the ability to produce several copies simultaneously in a single production run saves time, combined with an extrusion rate of 90mm³/s. This time saving also translates into an economic advantage: shorter manufacturing times mean lower production costs, which is essential if we are to remain competitive in a sector as demanding as watchmaking.

IDEX 3D printing offers the advantage of using technical materials tailored to the requirements of watchmakers. ANA 300X, the IDEX 3D printer, is equipped with a competitive thermal package (platen up to 150°C, additive head up to 500°C, enclosure heated to 60°C), which offers heat-resistant parts. This feature is particularly useful in processes where the 3D-printed support has to accompany the dial in extreme conditions, such as in the oven.

Conclusion

The manufacture of supports for watch dials illustrates how 3D printing can meet the unique requirements of the watchmaking industry. Thanks to technologies such as IDEX 3D printing, it is now possible to produce high-precision parts that meet the strictest tolerances while offering high repeatability, all simultaneously during the same operation.

While this application focuses on the manufacture of supports for watches, it demonstrates the many possibilities offered by 3D printing to demanding industries such as watchmaking.

usinage pièce métal Machining: metal parts machined in less than 1 hour? In a constantly evolving industrial environment, machine manufacturers are constantly …

Your industrial tools at your fingertips In a constantly evolving industrial environment, controlling the production of tooling is a key issue for …