Make your own industrial moulds with hybrid 3D printing

Industrial moulding is one of the fundamental processes in the manufacture of plastic parts. It involves the creation of moulds, enabling the mass production of objects with precise shapes. Traditionally, the manufacture of these moulds requires specialist sub-contracting.

The development of these moulds generally involves several trials of models, to ensure that they meet the technical specifications perfectly. This need for precision, combined with increasing demands, is driving manufacturers to look for more innovative and cost-effective solutions.

This is the context of the application presented in this article: the manufacture of moulds using 3D printing.

Context

The manufacturer HoliMaker is today presenting a new product offering in the field of industrial moulding: plastic injection moulding machines for prototyping. Aware of the challenges its customers face when developing new products, particularly when it comes to creating moulds for pre-production runs, HoliMaker decided to go one step further.

The company wanted to offer a complementary and innovative solution aimed at simplifying and optimising the process of designing and manufacturing industrial moulds. This initiative meets a growing need among its customers, who are looking to reduce costs, speed up time-to-market and ensure the quality of their prototypes before moving on to mass production.

Targets

The production of these pre-production moulds meets a number of specific requirements:

- These moulds will enable various iterations to be carried out before the final production run. This repetition is essential for carrying out a series of tests and making the necessary adjustments.

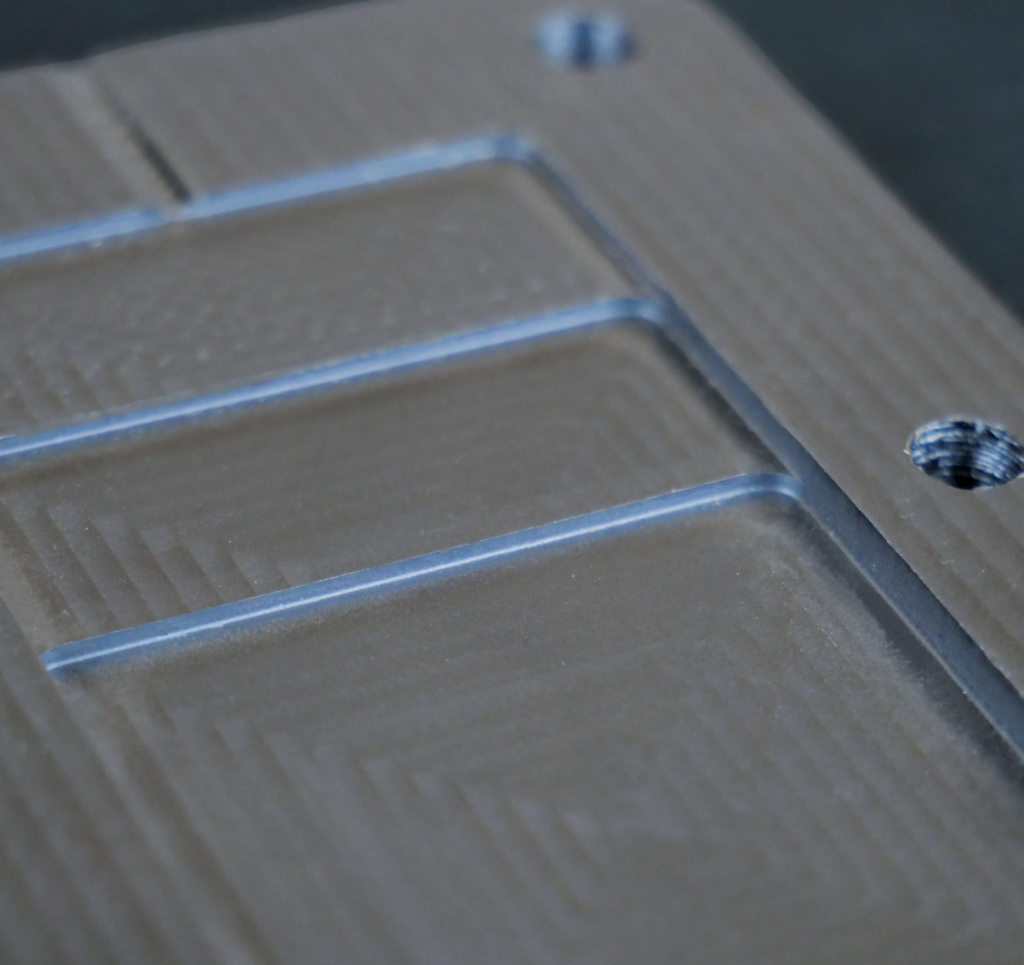

- Each mould must be made identically and precisely, ensuring uniformity between the different iterations. This precision avoids any variations that could affect the test results or compromise the quality of the final product.

- The mould material must be able to withstand high temperatures, up to 230°C on the surface. This thermal resistance is essential to guarantee the durability of the moulds during the test phases, which often involve extreme conditions, simulating the real environments to which the final product will be exposed.

- Finally, it is important to reduce both the time and costs involved in manufacturing these moulds.

Implementation and results

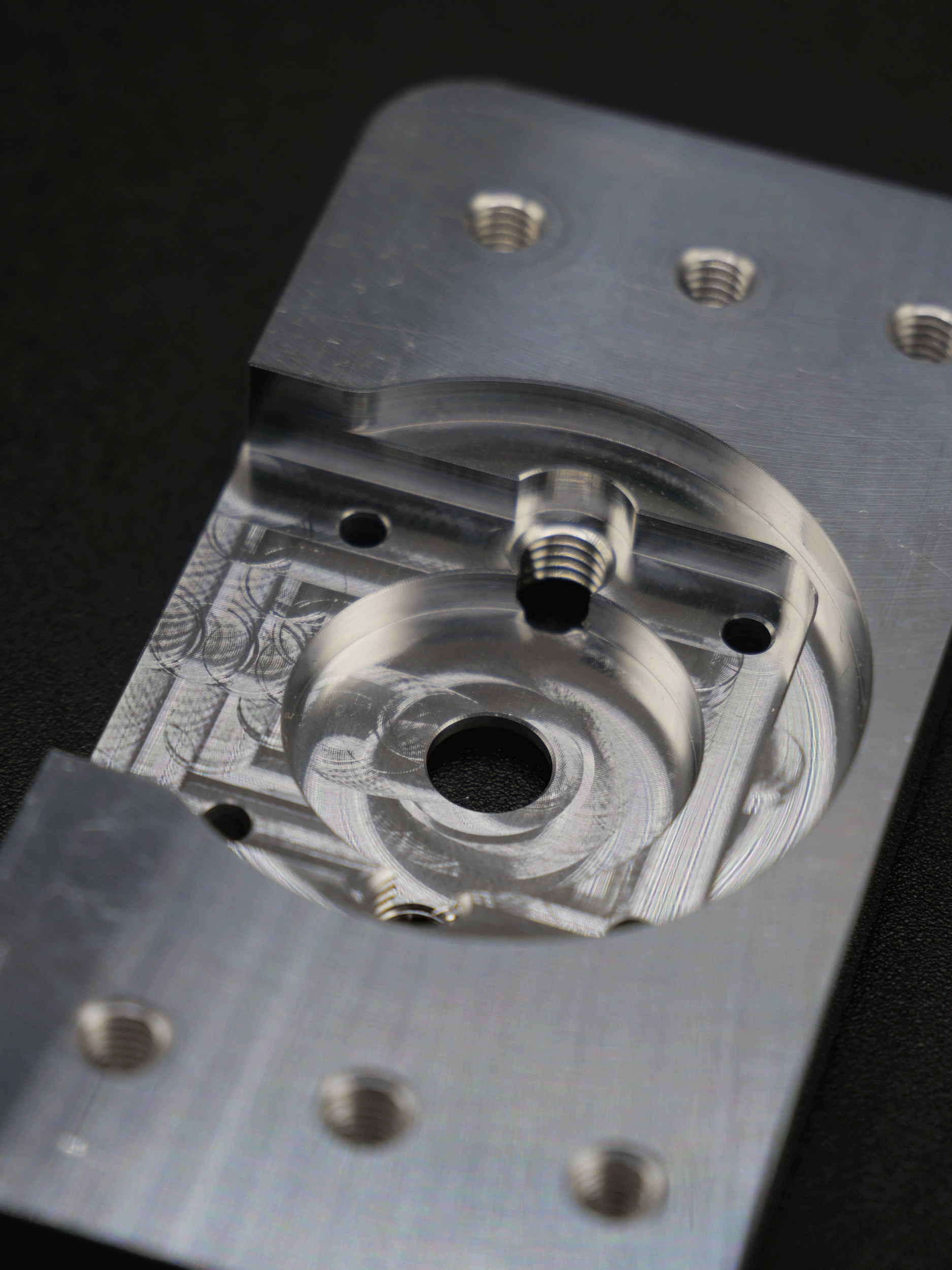

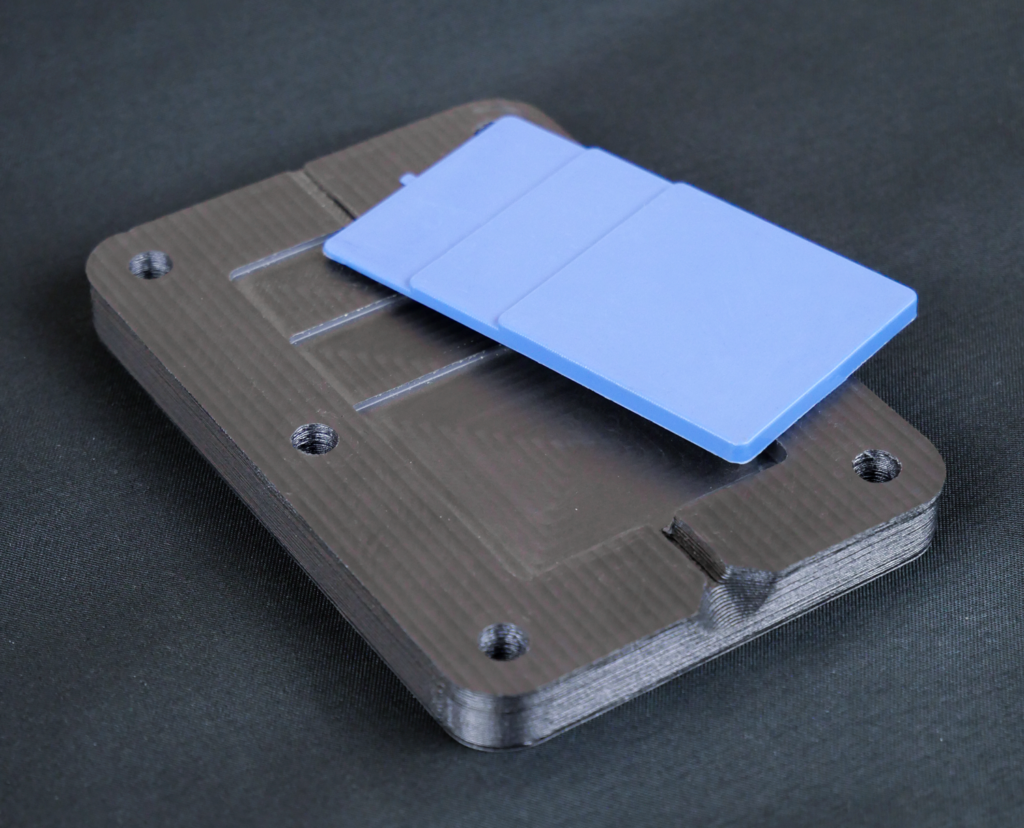

Namma and HoliMaker then collaborated to create an innovative and complementary offer that meets the specific needs of their customers in terms of industrial manufacturing. By combining the capabilities of HoliMaker’s press with the LUCY 300Y, Namma’s hybrid 3D printer, this collaboration opens up new possibilities in the creation of industrial moulds:

- The integration of hybrid 3D printing offers flexibility in customising iterations. Customers can adjust their moulds by quickly testing and modifying prototypes before finalising the product.

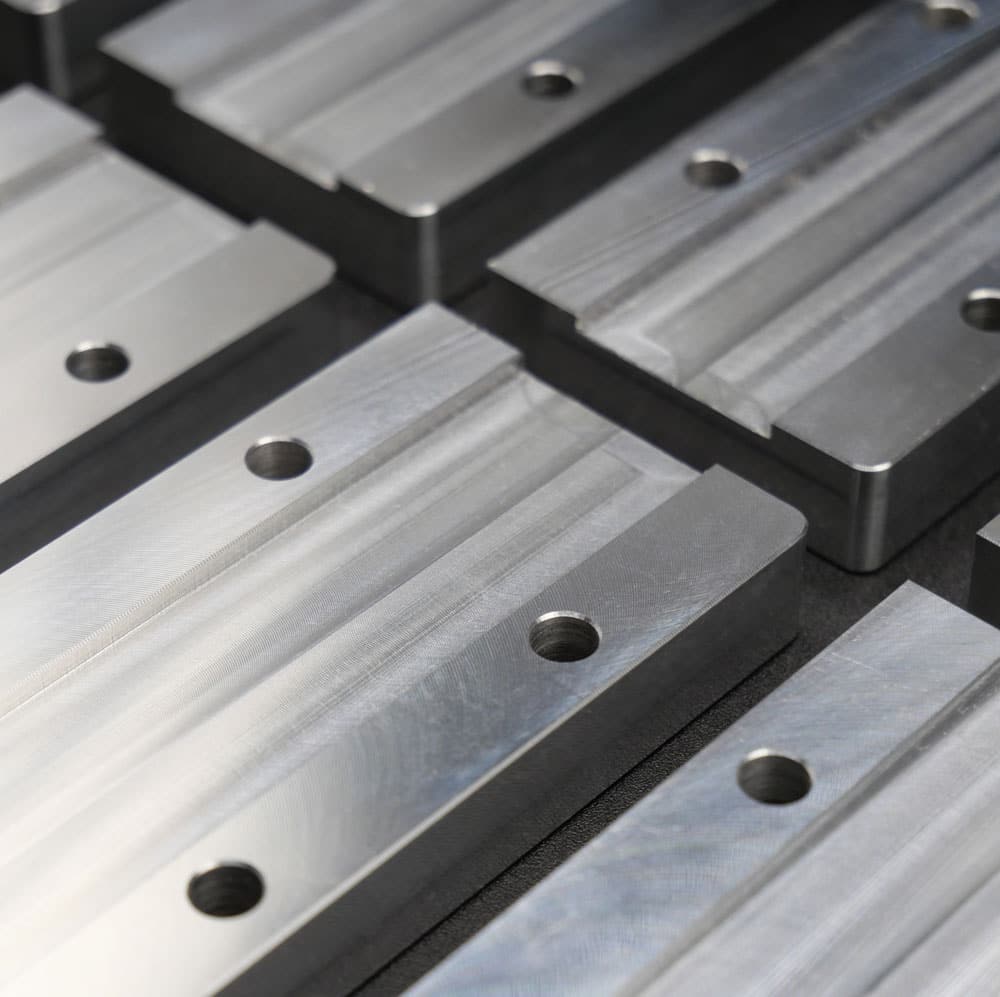

- The LUCY 300Y stands out for its integrated machining process, which enables smooth surface finishes to be achieved with an accuracy of up to 0.3 µm in Ra. This technology is particularly useful for industries requiring tight tolerances and a high-quality finish.

- In addition, the possibility of using heat-resistant materials, such as PPS CF, which can withstand continuous temperatures of up to 220°C, broadens the range of possible applications.

- Another major advantage of this collaboration is the reduction in manufacturing times. Whereas the creation of a mould by a subcontractor would usually take between 8 and 12 weeks, by bringing hybrid 3D printing technology in-house, the LUCY 300Y can be manufactured in just 56 minutes per part. By producing the parts they need themselves, in real time, HoliMaker’s customers can not only reduce their development costs, but also be more responsive to market demands.

Conclusion

This approach allows customers to control the entire product development process, from mould design to injection moulding of plastic parts. This manufacturing autonomy guarantees not only total control over quality and lead times, but also greater flexibility to respond to specific market needs, boosting the company’s competitiveness.

usinage pièce métal Machining: metal parts machined in less than 1 hour? In a constantly evolving industrial environment, machine manufacturers are constantly …

Your industrial tools at your fingertips In a constantly evolving industrial environment, controlling the production of tooling is a key issue for …