3D printing: the solution for a better industrial ecology ?

Climate change is now a fact of life and continues to fuel discussions in scientific circles and political decision-making. The effects of global warming, caused by high greenhouse gas emissions, are well known. Average temperatures are slowly rising, and meteorological phenomena are becoming more extreme.

Industrial production has a significant influence on this ecology, not only because of the energy consumed in manufacturing, but also because of the energy expended in transporting raw materials and products through logistics networks. A growing number of companies and consumers are therefore moving towards more environmentally-friendly and sustainable models.

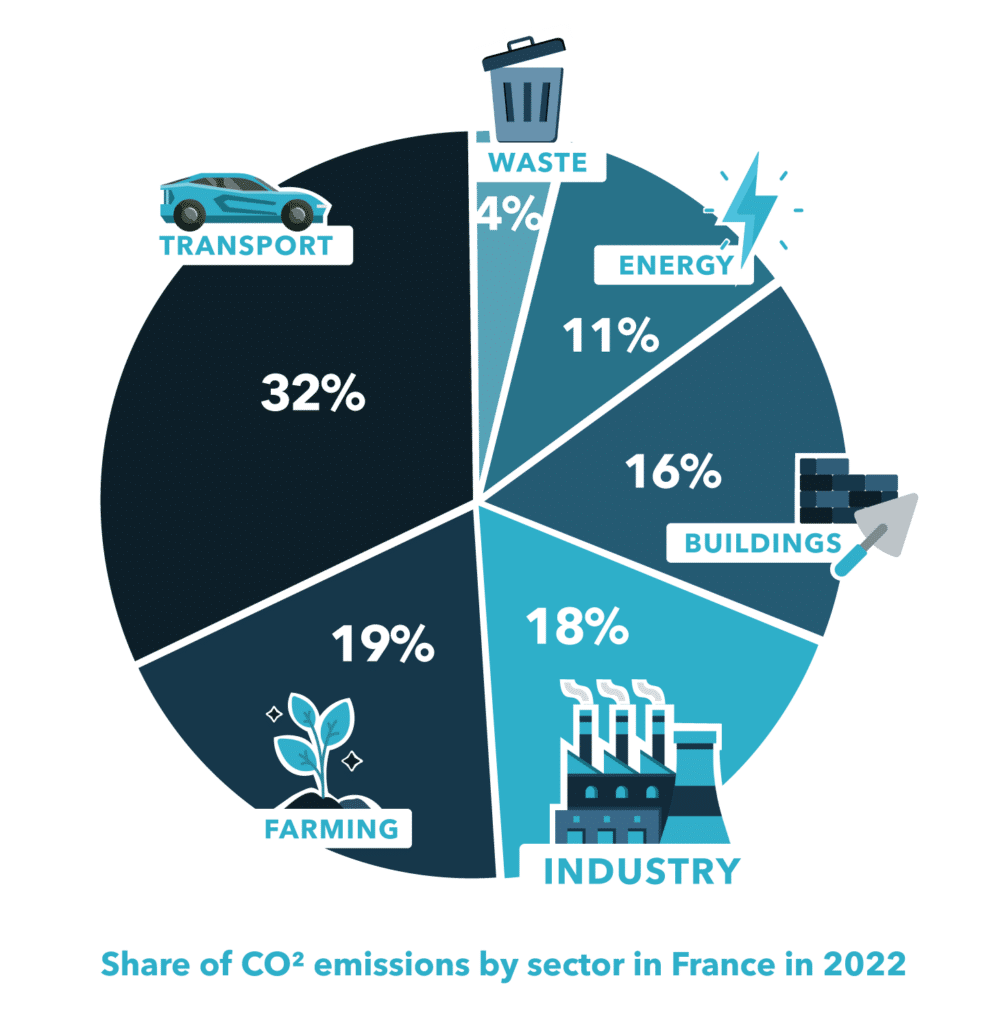

In 2022, French industry ranked third among the most polluting sectors. This sector alone was responsible for 18% of national CO² emissions, representing around 73 million tonnes of CO². Despite this worrying position, the industrial sector still ranked behind two other major emitters. In first place, the transport sector accounted for 32% of total emissions, reflecting the increasing reliance on motorised vehicles and massive logistics systems, both for private individuals and for commerce, while agriculture came second with 19% of emissions.

Why would a company in the industrial sector want to reduce its carbon footprint?

There are a number of strategic and ethical reasons for a company in the industrial sector to want to reduce its carbon footprint. Optimising manufacturing processes, by reducing waste and energy consumption, not only improves operational efficiency but also ensures greater compliance. This enables companies to cut costs while meeting the growing expectations of consumers, for whom sustainability has become an essential standard.

Indeed, integrating a corporate social responsibility (CSR) approach strengthens a company’s economic performance. According to a study by France Stratégie in 2016, companies with a solid CSR strategy recorded an average 13% increase in their performance. By reducing energy consumption or cutting waste, such an approach contributes directly to cost reduction.

Another study carried out in January 2024 by CCI France confirms this trend: 74% of French people would recommend a company actively committed to CSR, and 68% would be prepared to buy its products or services more frequently. CSR is thus becoming a lever for differentiation, enabling companies to access new markets and build customer loyalty.

For an industrial company regularly confronted with environmental issues, a CSR strategy becomes essential not only to improve its brand image, but also to reduce the risks associated with regulatory constraints and societal expectations over the medium and long term. Reducing our carbon footprint is therefore both an economic and regulatory imperative, and a way of remaining competitive.

The ecological benefits of 3D printing

There are many ways for a company in the industrial sector to reduce its carbon footprint, by adopting various strategies aimed at optimising production processes or limiting direct CO2 emissions. Among these methods, the one we are going to develop here is based on an innovative approach: the integration and use of 3D printers in place of traditional production machines for prototyping and tooling.

Reducing waste

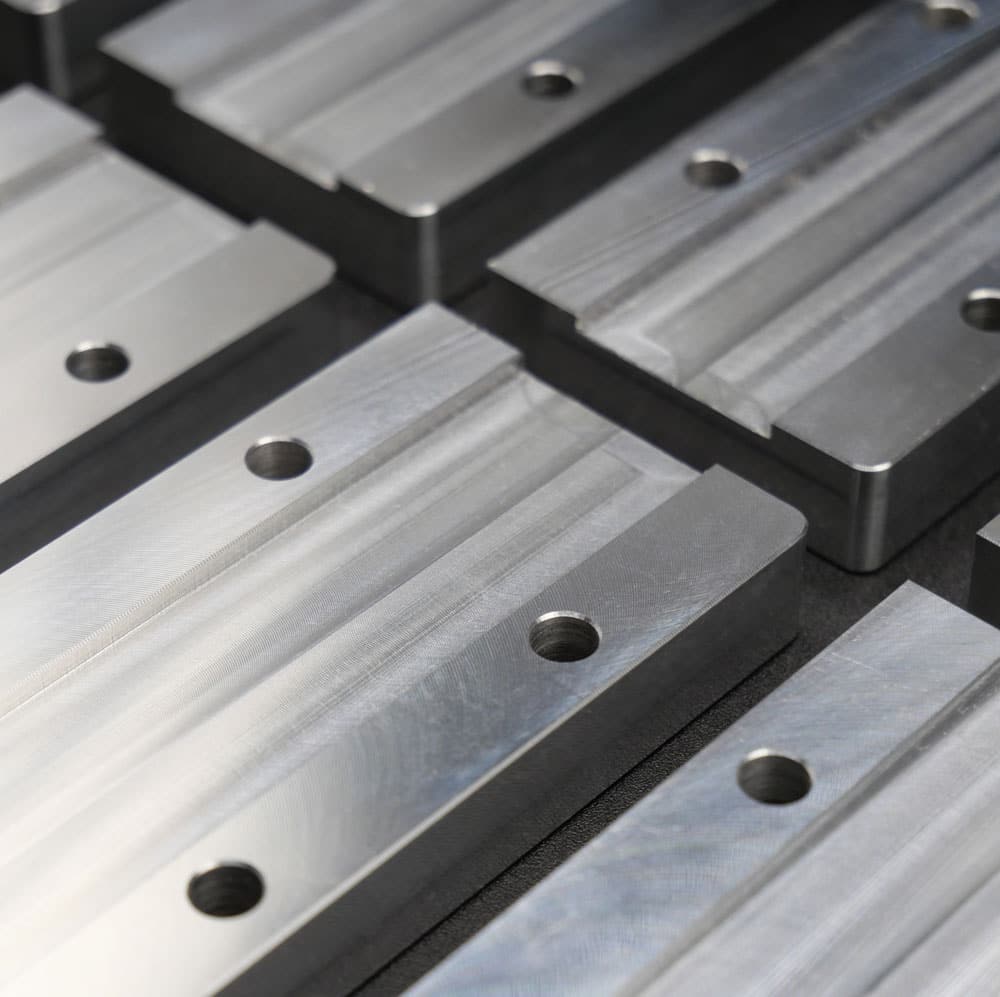

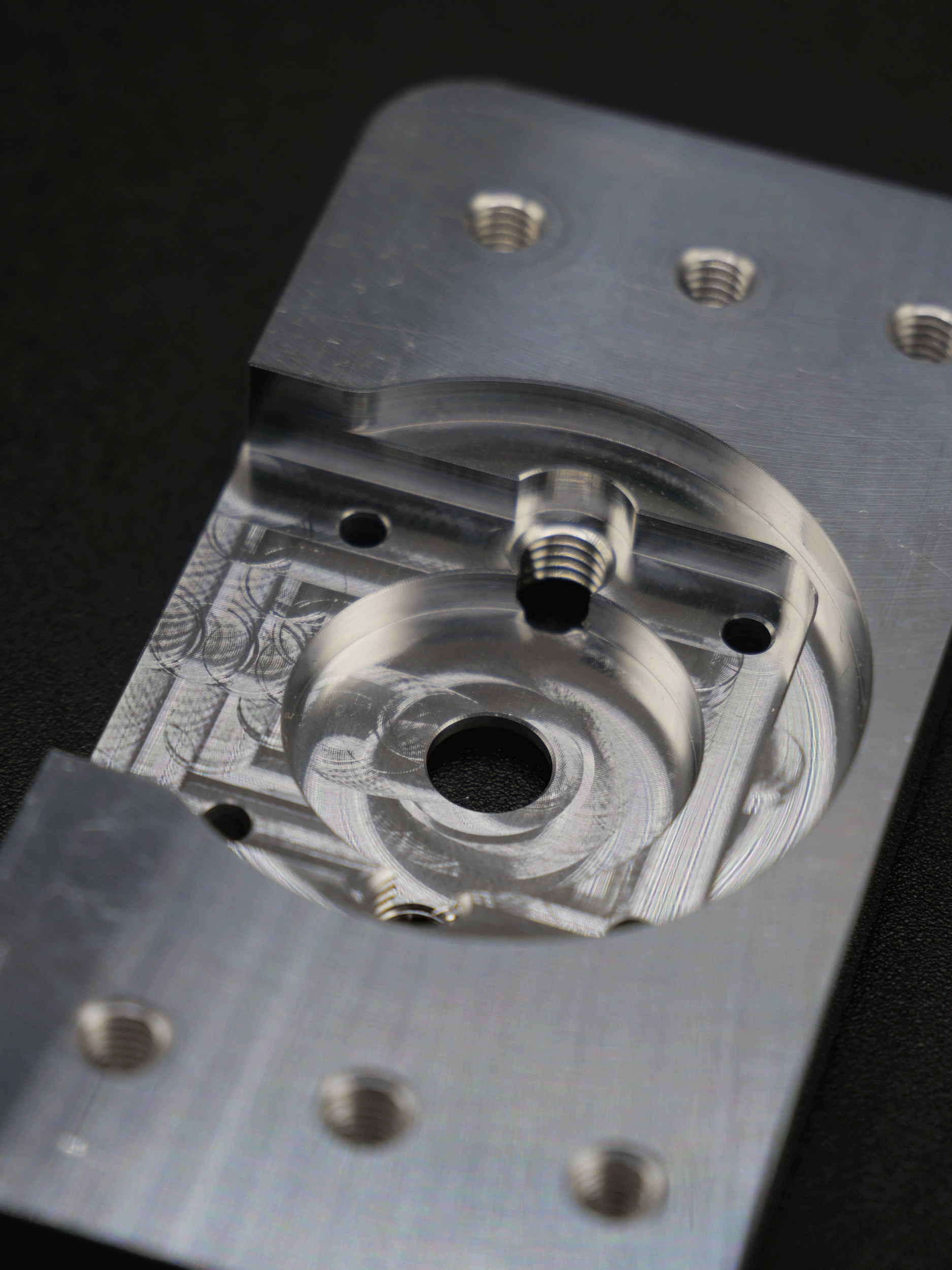

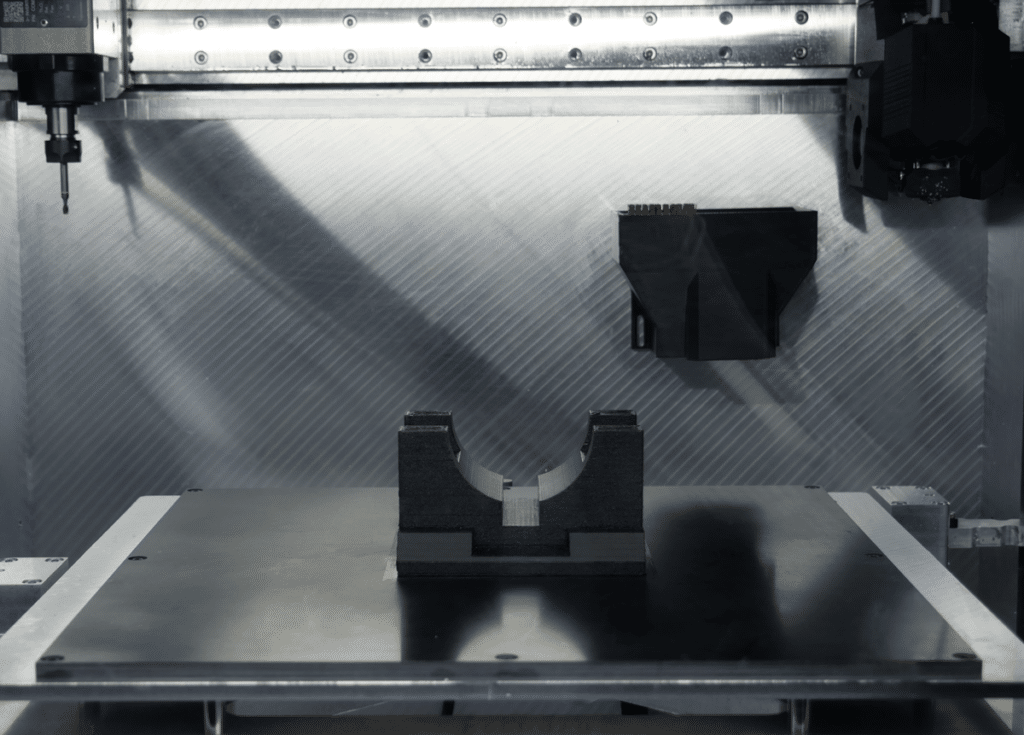

Traditional machines encompass different manufacturing technologies. One of the most common traditional machines is machining. This process involves removing portions of a raw material to obtain the desired shape using cutting tools. However, this traditional approach generates a lot of waste in the form of swarf. 3D printers make more efficient use of resources by reducing the waste generated, unlike traditional machines, which produce up to 80% of production waste.

3D printing works differently: it relies on the successive addition of thin layers of material to build an object, layer after layer. This means there is no waste, because there is no excess material or unnecessary residue. The quantity of material used is exactly the same as that needed to manufacture the part, which eliminates any waste of materials.

More efficient use of energy

Reducing the quantity of raw material also reduces the energy required for production. Machines operate more efficiently because they don’t waste energy processing unnecessary materials. This energy optimisation also means lower emissions from the manufacturing process, particularly in terms of carbon and heat, which helps to make production more environmentally friendly.

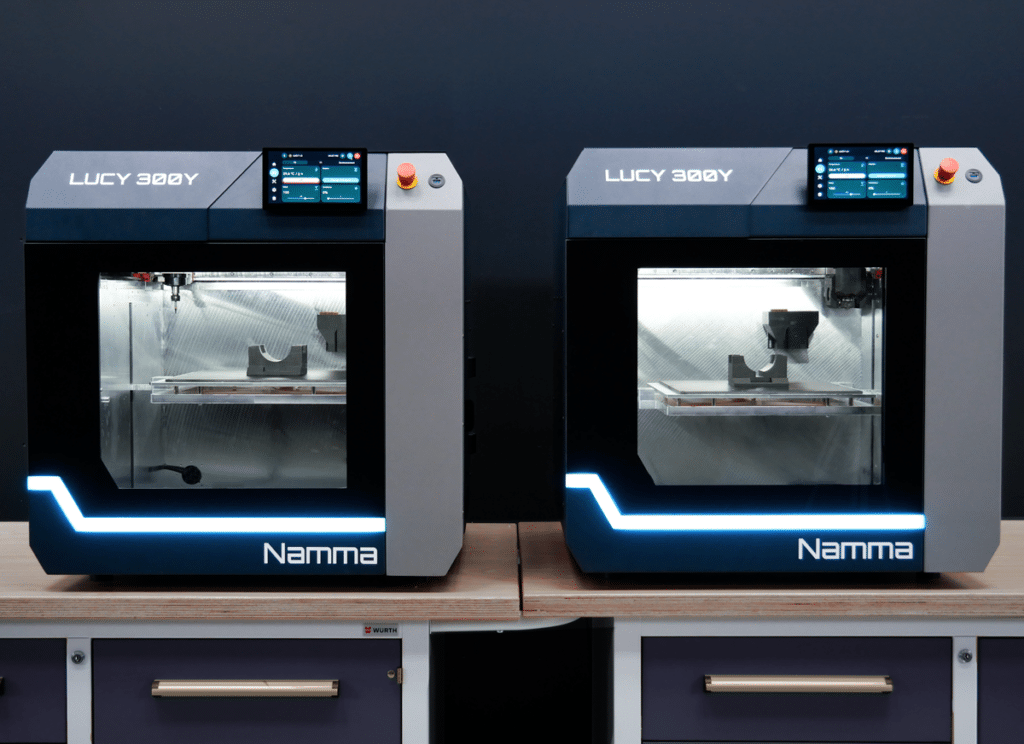

Another 3D printing technology, hybrid 3D printing, which integrates several processes in a single machine, further enhances these benefits. By combining different additive and subtractive manufacturing technologies in a single device, it is possible to carry out several processes without having to transfer parts from one machine to another. By combining several machines into one, energy consumption and carbon emissions are reduced. To find out more about hybrid 3D printers, visit the LUCY 300Y hybrid 3D printer page.

Shortening the supply chain

3D printers offer the advantage of shortening supply chains by reducing reliance on subcontracting. By bringing the production of parts in-house, companies can manufacture what they need directly on site, without having to use external suppliers. This considerably simplifies logistics and reduces the time taken to deliver components. Integrating a 3D printer into a company’s operations means that maintenance parts requirements can be met quickly. As soon as a piece of equipment breaks down or requires repair, the missing parts can be produced on demand, eliminating the wait associated with ordering and delivering spare parts.

This not only avoids prolonged interruptions to operations, but also reduces the overproduction of parts upstream, which in traditional methods often leads to surplus stocks. By reducing stocks and overproduction, they optimise their resource management and save on storage costs.

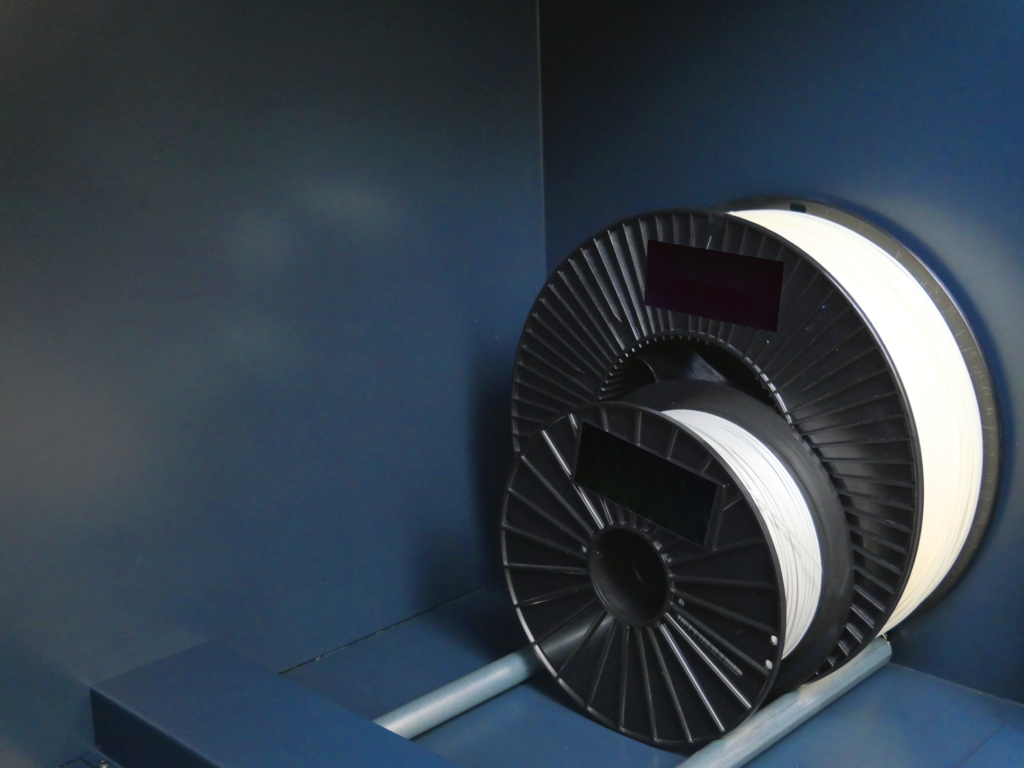

Eco-responsible materials

In addition to the technical and economic advantages of 3D printing, the use of bio-sourced and recycled materials makes it possible to adopt a more environmentally-friendly approach. Bio-sourced materials, derived from renewable resources such as plants or organic waste, are a sustainable alternative to traditional materials. Recycled materials, meanwhile, play a key role in the circular economy. 3D printing makes it possible to use raw materials from industrial or post-consumer waste, which would otherwise be sent to landfill or incinerated. Thanks to this technology, this waste is recovered and transformed into new products, thereby reducing the amount of waste put into circulation and helping to preserve natural resources.

Traditional materials include those made from natural products, such as PLA, which is derived from corn starch. However, it is important to remember that these materials are still plastics, whose environmental impact is generally higher than that of bio-sourced or recycled materials.

The ecological limits of 3D printing

Although 3D printers offer significant environmental benefits, they also generate emissions of volatile organic compounds (VOCs) during the manufacturing process, particularly as a result of the melting and deposition of the materials used. These VOCs can have harmful effects on air quality and potentially on the health of operators if they are not properly contained.

However, these emissions can be effectively managed through the use of appropriate systems. In particular, by integrating a closed enclosure around the printer, thus limiting the dispersion of VOCs in the working environment. In addition, filtration systems are also essential to purify the air inside this enclosure, capturing and neutralising VOCs before they can escape. These solutions are already integrated into the industrial 3D printers developed by Namma. By combining these two approaches – a hermetic enclosure and an advanced filtration device – it is possible to exploit the benefits of 3D printing while ensuring a healthier working environment and reducing the impact of VOC emissions on the global environment.

Conclusion

Faced with the growing need to reduce greenhouse gas emissions, industrial companies can turn to innovative solutions to limit their carbon footprint. The integration of technologies such as 3D printing represents an effective response to this challenge, making it possible to reduce production waste, optimise energy consumption and cut logistics. Although environmental challenges remain, particularly in terms of emissions of volatile organic compounds, technical measures such as the use of filtration systems and closed enclosures can limit these impacts. By adopting these practices, industrial companies can reconcile economic performance, cost reduction and respect for society’s expectations in terms of environmental responsibility.

usinage pièce métal Machining: metal parts machined in less than 1 hour? In a constantly evolving industrial environment, machine manufacturers are constantly …

Your industrial tools at your fingertips In a constantly evolving industrial environment, controlling the production of tooling is a key issue for …