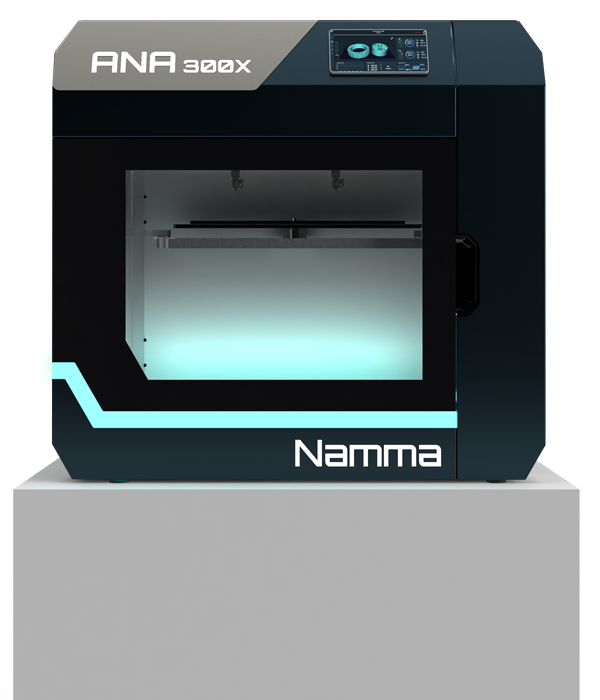

Hybrid 3D Printer

LUCY

3D PRINTING AND CNC MACHINING

| AT THE SAME TIME

Gain in precision and quality

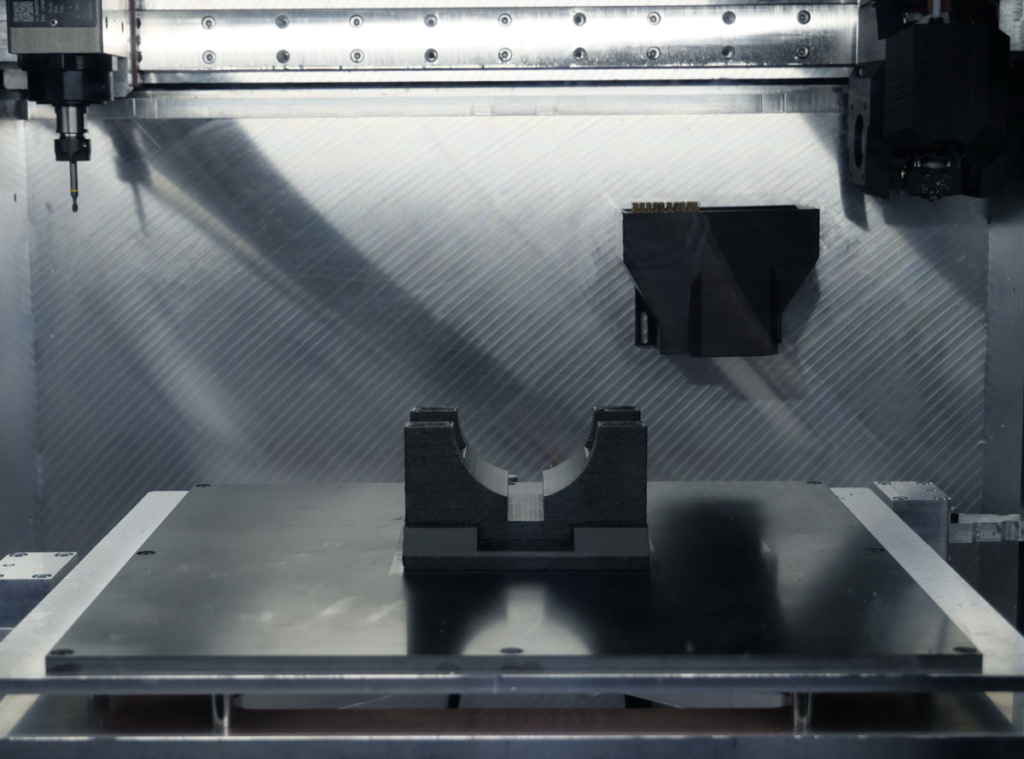

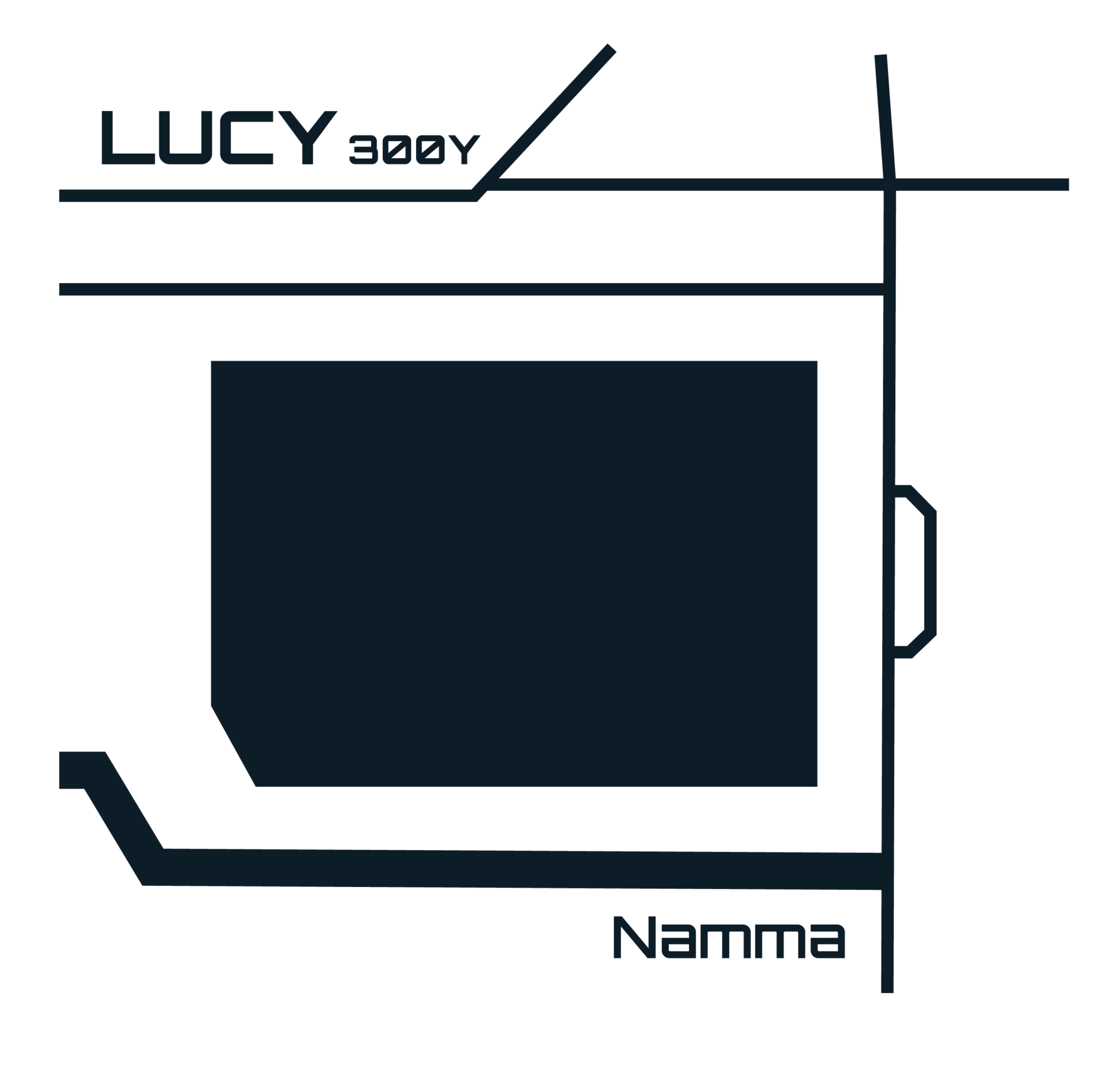

LUCY 300Y is a hybrid machine: it automatically combines 3D printing and machining simultaneously, enabling you to manufacture complex parts quickly.

Manage your projects easily and intuitively thanks to the integrated management software: N-Play.

Produce precise parts: Achieve surface finishes of 0.3µm and dimensional tolerances of ±0.05mm.

Designed for the industrial environment, the parts produced by LUCY 300Y can be used directly, eliminating the need for additional post-processing steps.

Trusted by

Hybrid 3D printer

LUCY

3D PRINTING AND CNC MACHINING

AT THE SAME TIME

Trusted by

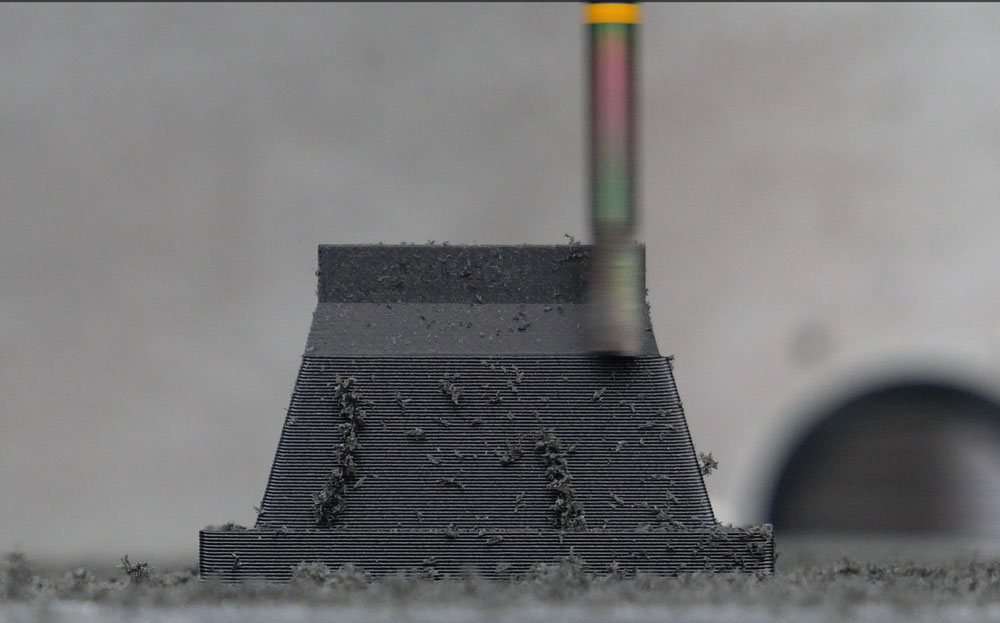

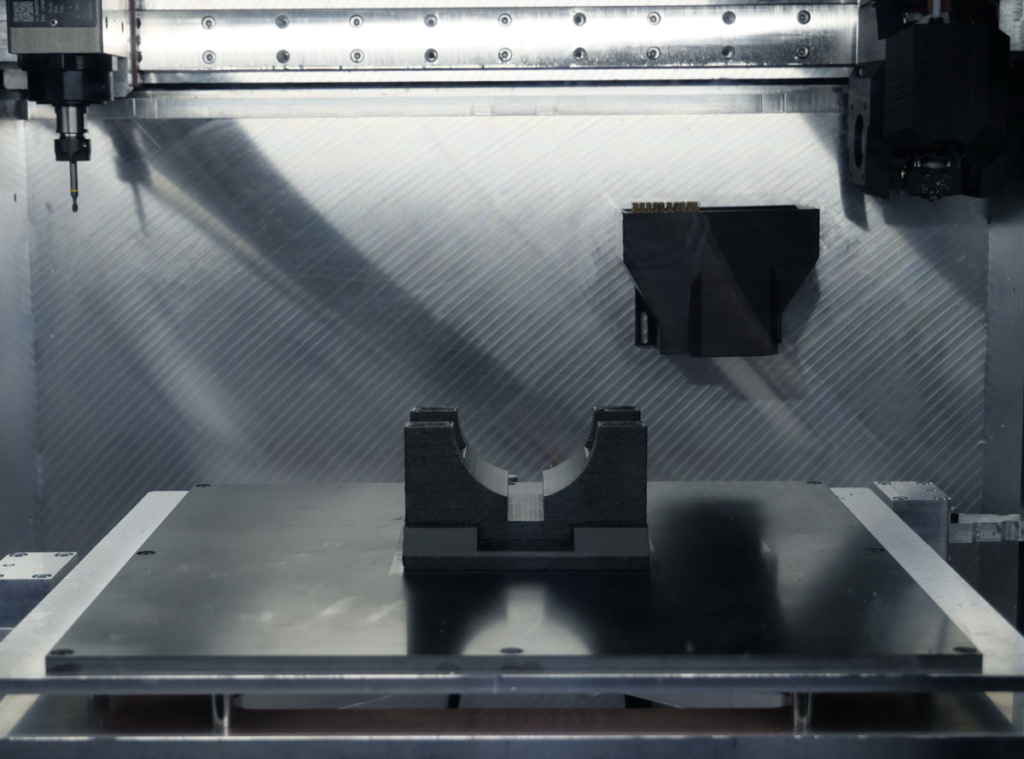

Two independent integrated heads

SIMULTANEOUS 3D PRINTING

AND MACHINING

Make complex, precise parts by combining the simplicity of 3D printing with the precision of machining. The parts can be used directly, eliminating the need for additional post-processing steps.

Surface finishes

0,3μm

Dimensional tolerances

±0,05mm

High extrusion output

90mm3/s

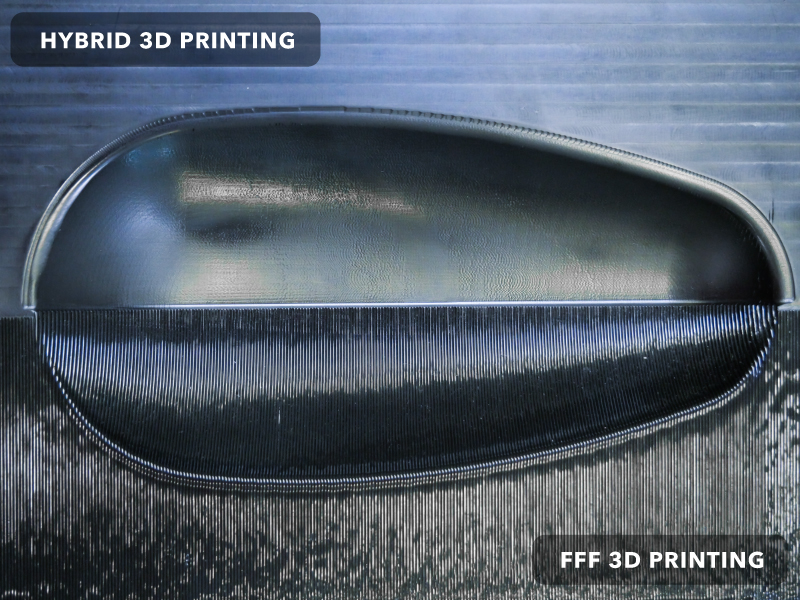

What is hybrid 3D printing?

Hybrid 3D printing combines 2 processes in 1 machine: additive manufacturing with 3D printing and subtractive manufacturing with CNC machining. The steps follow one another automatically until you arrive at the final part.

1

3D PRINTING

2

MACHINING

3

ALTERNATE

4

FINAL PART

The benefits of hybrid 3D printing

By combining the additive and subtractive environments simultaneously, you can achieve surface finishes down to 0.3µm and precise dimensional tolerances down to ±0.05mm.

Simple 3D printing and precision machining

Reducing lead times

by 10

Manufacturing

of complex parts

Mass-produced parts at the best price

High-quality 3D printing

With LUCY 300Y, post-treatment steps are a thing of the past. It guarantees cutting-edge performance with high-strength, high-temperature materials.

High-temperature components

bed : 150°C

Coil compartment and environment

heated to 60°C

Robust chassis and precise transmission system

A WIDE CHOICE OF INDUSTRIAL MATERIALS

Choose the materials that meet your requirements from a wide range of filaments and take advantage of Namma’s range of industrial materials: N-MAT.

N-MAT

- N-PETG CF

- N-PA6 CF

- N-ABS

- N-PETG

- N-PA6

- N-ASA

- N-ABS CF

- N-ABS INDUS

- N-PA12 CF

- N-PC ABS

- N-ABS ESD

- N-PETG ESD

- N-ABS ARAMID

- AND MORE

DIRECTLY USEABLE parts

Take advantage of dimensions of 300mm x 300mm x 300m, suitable for industrial manufacturing.

Prototype, tooling, final part, mould, spare part, in series

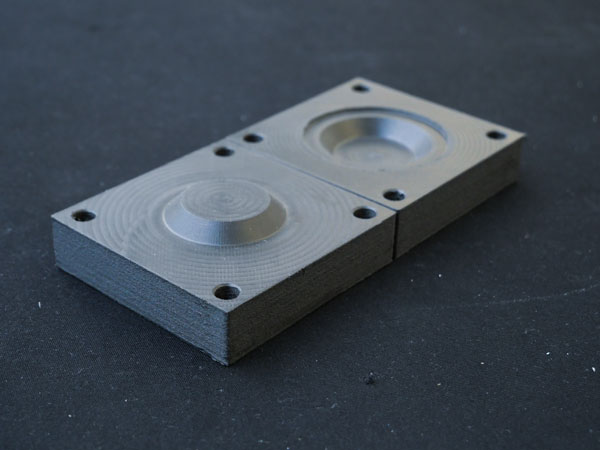

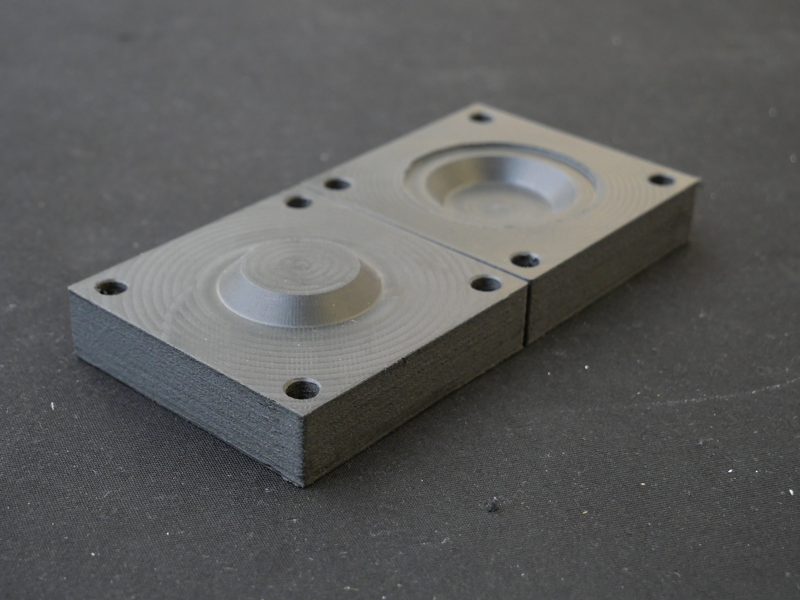

PRE-PRODUCTION MOULD

Materials

N-PETG CF

Dimensions

80mm x 80mm x 24mm

Production time (units)

55min

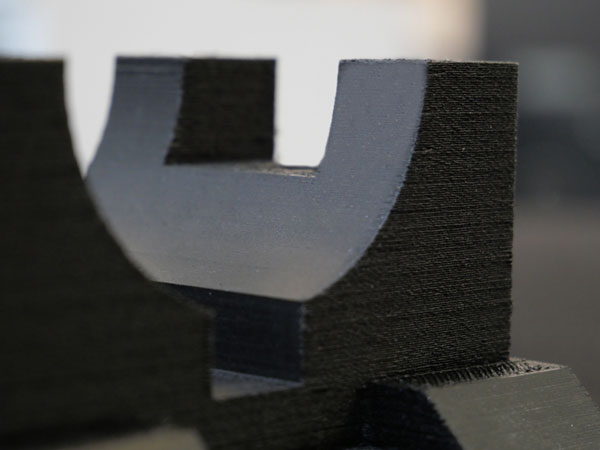

MOUNTING BRACKET

Materials

N-PETG CF

Dimensions

100mm x 79mm x 55mm

Production time (units)

1h42

BEARING SUPPORT

Materials

N-ABS CF

Dimensions

83mm x 44mm x 19mm

Production time (units)

34min

PARTS THAT CAN BE USED DIRECTLY

No additional post-processing steps

Mould

Pre-production mould

Materials : N-PETG CF

80mm x 80mm x 24mm

Manufacturing time : 55min

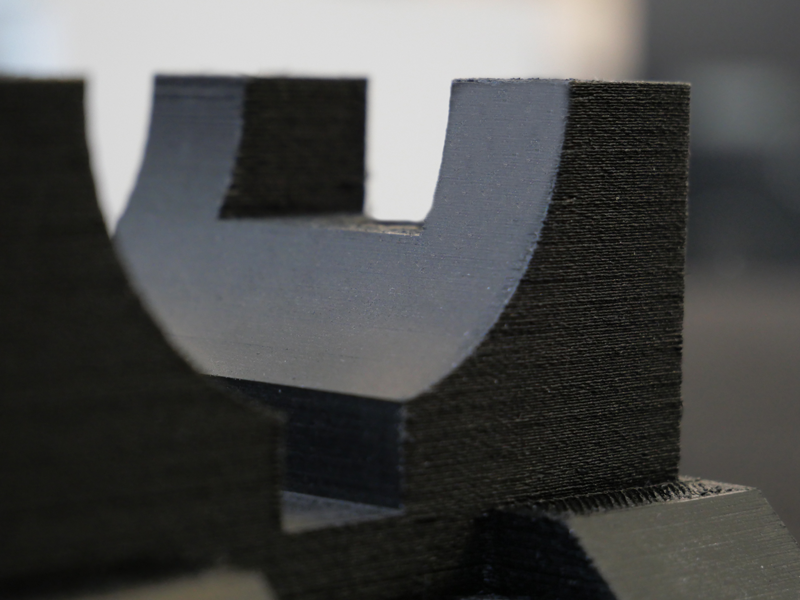

Tooling

Mounting bracket

Materials : N-PETG CF

100mm x 79mm x 55mm

Manufacturing time : 1h42

Final part

Bearing support

Materials : N-ABS CF

83mm x 44mm x 19mm

Manufacturing time : 34min

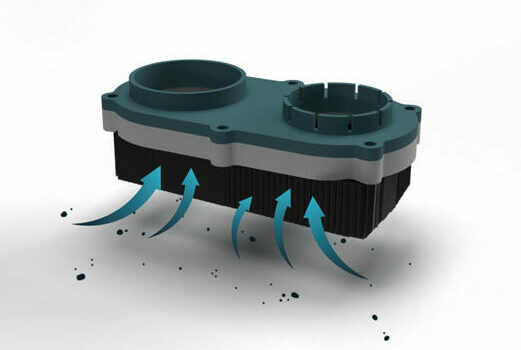

Filtration system

LUCY has a filtration system designed to capture extremely fine particles. LUCY’s H14 HEPA filters offer one of the highest filtration efficiencies available to ensure maximum safety.

Chip extraction

LUCY is equipped with a chip extraction system, guaranteeing a clean and healthy environment.

Certified machines

All Namma machines are CE certified in accordance with the Machinery Directive 2006/42/EC and comply with strict safety, health and protection standards. This certification makes it easier for you to integrate and install your future Namma machines in your company.

Comprehensive support

Namma offers you complete support from the moment you acquire a machine. Take advantage of training and maintenance for your Namma machines.

Accessible and Intuitive

The LUCY 300Y incorporates N-Play control software, directly accessible on a 7’ touch screen. This software allows you to control the machine simply and intuitively. Accessible to all types of user.

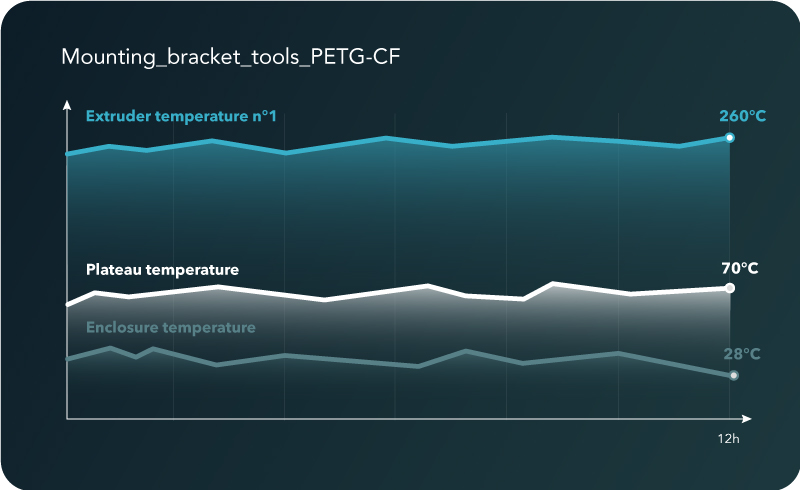

Control your 3D printing

Monitor your production thanks to print logs supplied directly in the Namma machine control software. Graphs give you access to temperature history for better traceability.

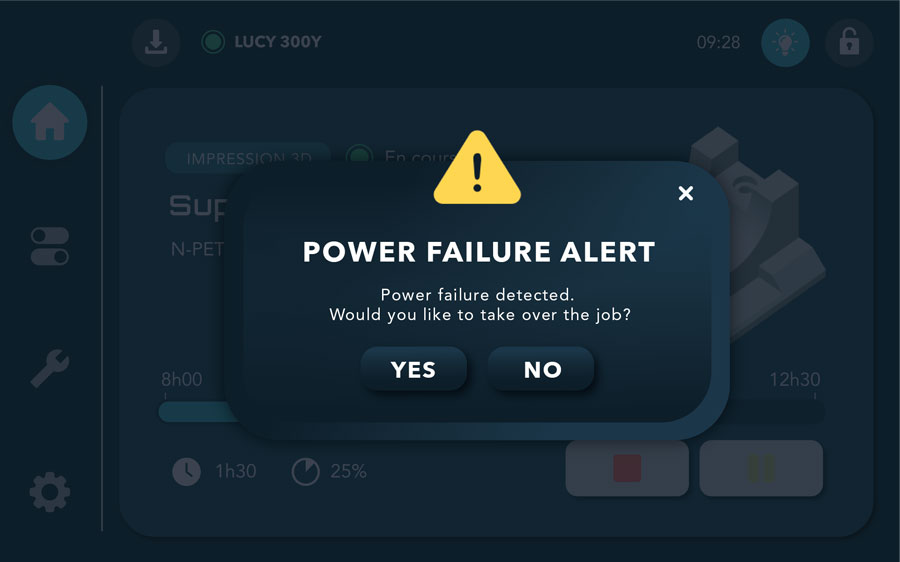

Secure your production

N-Play offers you a secure environment for your production: it is equipped with a filament end detector and automatic resumption of printing after a shutdown or machine stoppage.

Made in France

Namma 3D printers are manufactured and assembled directly on our premises in Bordeaux. This environment means we can stay close to you and respond quickly to your needs.

By using French production methods, we can offer you high-quality, robust industrial products that comply with industry standards.

LUCY adapts to your needs

Tool-head temperature :

Up to 300°C

Up to 500°C

Bed temperature :

Up to 120°C

Up to 180°C

Extrusion rate :

Up to 30 mm3/s

Up to 90 mm3/s

Heated enclosure

STANDARD

PREMIUM

LUCY adapts to your needs

STANDARD

Tool-head temperature – 300°C

Bed temperature – 120°C

Extrusion rate – 30 mm3/s

PREMIUM

Tool-head temperature – 500°C

Bed temperature – 180°C

Extrusion rate – 90 mm3/s